Fastest cutting speeds and best precision compared to any competitive abrasive waterjet in the industry

Backed by our exclusive Intelli-MAX Software with real world cutting data

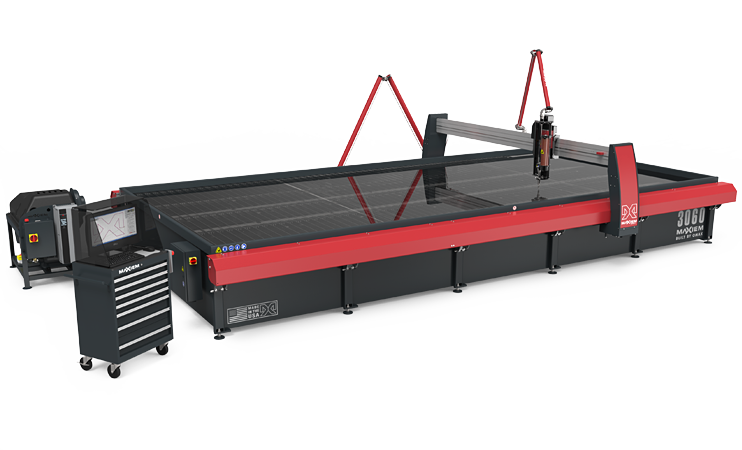

Small, efficient footprint for minimal floor space utilization

The mobile control station allows operators direct and efficient access to the cutting process with storage for all of the tools and spares

Powerful all-in-one controller computer with large 23" screen

Drive system sealed against water, dirt, and grit

No tool changes & minimal fixturing dramatically reduce setup

Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

Does not create heat-affected zones or mechanical stresses

Leaves behind a satin-smooth edge, reducing secondary operations

No noxious gases, liquid or oils used in, or caused by, the machining process

Environmentally "green" system with quiet and clean operation with low electrical consumption

Shipped as a completely pre-assembled and factory-tested system

Designed and manufactured at the OMAX factory in Kent, Washington, USA

Standard patent-pending Intelli-TRAX traction drive inside the X-Y Axis beams fully enclosed inside coated steel covers

Standard Intelli-VISOR SE System Monitoring offers predictive maintenance and system monitoring to minimize unexpected downtime

Standard programmable Motorized Z-Axis with a precision OMAX MAXJET 5i Nozzle boosts productivity and process efficiency

Standard scissor-style hard plumbing adds another level of safety by using contained high-pressure components, as well as contributes to a smaller footprint, lower maintenance, and higher reliability

Optional Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

Optional Bulk Abrasive Delivery System transports garnet from the assembly's large hopper into the Zero Downtime Hopper located on the Z-Axis

Optional Variable Speed Solids Removal System (VS-SRS) designed for industrial use increases uptime through automated solids removal

Optional Intelli-CAM software program is available with two tools in one that can generate either 2D or 3D tool paths from 3D models.

Highly efficient, industry-proven direct drive pumps available up to 40 hp with operating efficiencies up to 85%

Uses substantially less cooling water than inefficient hydraulic intensifier pumps

Lowest electrical consumption compared to other pump technology