SLTL Infinity F1 2D Fiber Laser

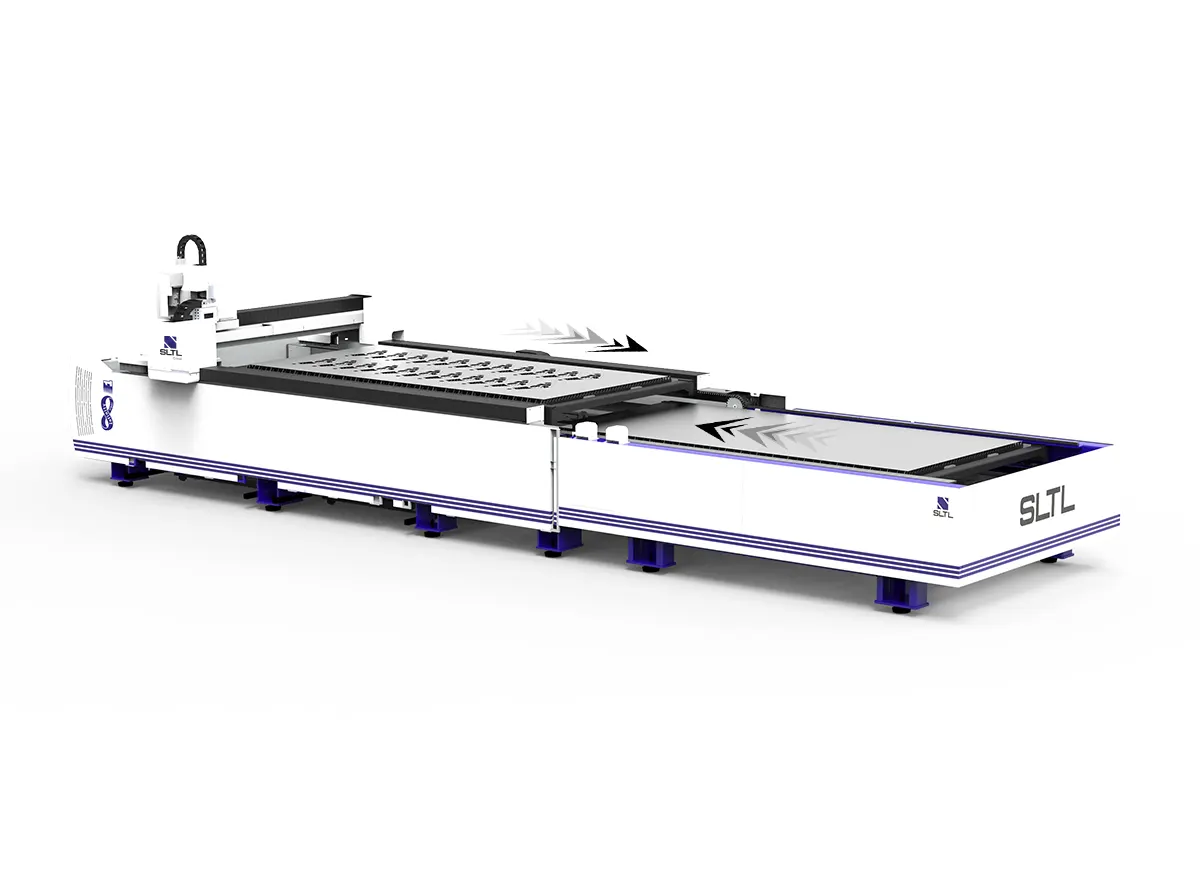

SLTL Group, India’s first fiber laser cutting machine inventor & manufacturer has designed the ‘Infinity’ 2D fiber laser cutting system. It is known for its extensiveness considering the specific needs of the metal cutting industry. Its vigorous flexibility extends thunderbolt reflexes for swift material change. A hermetically sealed cabinet keeps safety at its best. This automatic sheet metal cutting machine takes a very low time for booting. A High-end 64-bit CNC controller is equipped with a user-friendly operating interface. The magnificent controller responds within 20 nanoseconds which makes the Infinity super responsive.

| Unit | Working Range 2D | |||||||

|---|---|---|---|---|---|---|---|---|

| 1515 | 3015 | 4020 | 6520 | 6525 | 8025 | |||

| Maximum Working Range | X Axis | mm | 1525 (60.03″) | 1525 (60.03″) | 2100 (82.6*) | 2100 (82.6″) | 2550 (100.3″) | 2550 (100.3″) |

| Y Axis | mm | 1525 (60.03″) | 3100 (122*) | 4100 (161.4″) | 6600 (259.8*) | 6600 (259.8″) | 8050 (316.9″) | |

| Z Axis | mm | 150 (5.9″) | 299 (11.8″) | 300 (11.8″) | 301 (11.8″) | 302 (11.8″) | 450 (17.7″) | |

| Z Axis (UHP) | mm | 150 (5.9″) | 300 (11.8″) | 300 (11.8″) | 301 (11.8″) | 450 (17.7″) | 451 (17.7″) | |

| Maximum Workpiece Weight*** | kgs | 220 | 900 | 1650 | 2650 | 3100 | 7800 | |

| (UHP) | kgs | 220 | 1100 | 3150 | 5100 | 6350 | 7800 | |

| Positioning Precision | mm/m | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| Repeatability | mm/m | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | |

| Maximum Rapid | Simultaneous | m/min | 120 | 170 | 125 | 125 | 125 | 125 |

| Maximum Acceleration | m/s2 | 20 | 20 | 15 | 15 | 15 | 15 | |

| Laser Power | 3 kW | 4 kW | 6 kW | 8 kW | 10 kW | 12 kW | 15 kW | 20 kW | 30 kW |

|---|---|---|---|---|---|---|---|---|---|

| Cutting Thickness on Metals mm (inch) | |||||||||

| Mild Steel (MS) (02) | 20 (3/4″) | 22 (7/8″) | 25 (1″)* | 28 (9/8″)* | 30 (19/16″)* | 40 (25/16″)* | 45 (7/4″)* | 50 (31/16″)* | 60 (19/8″)* |

| Mild Steel (MS) (N2 / Air) | 6 (1/4″) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* |

| Stainless Steel (SS) (02) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″)* | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) |

| Stainless Steel (SS) (N2 / Air) | 8 (5/16″) | 10 (3/8″) | 16 (5/8″)* | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Aluminum (AL) (N2) | 8 (5/16″) | 10 (3/8″) | 16 (5/8″)* | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Brass (Br) (N2) | 6 (1/4″) | 8 (5/16″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* |

| Copper (Cu) (02) | 5 (3/16″) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 16 (5/8″) | 18 (11/16″) | 20 (13/16″) | 22 (7/8″) |

| Galvanized Iron (GI) (N2 / Air)# | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) |

| Power Consumption** | 20 kW | 24 kW | 32 kW | 40 kW | 48 kW | 56kW | 68kW | 85kW | 120kW |

| Type | Working Area (2D) | |||||

|---|---|---|---|---|---|---|

| 1515 | 3015 | 4020 | 6520 | 6525 | 8025 | |

| Machine Width | 2820 | 2280 | 3400 | 3300 | 3900 | 3900 |

| Machine Height | 2300 | 2190 | 2200 | 2200 | 2200 | 2350 |

| CNC Gantry | 4700 | 6000 | 6700 | 9300 | 9300 | 10900 |

| Dual Pallet | NA | 3300 | 4400 | 6900 | 6900 | 8500 |

| Total Machine Length | 6700 | 9300 | 11100 | 16200 | 16200 | 19400 |

| Space Required for Accessories | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Total Machine Width with Accessories | 3300 | 4280 | 5900 | 5900 | 6500 | 6500 |

| Width of Operating Panel | 600 | 600 | 600 | 600 | 600 | 600 |

| Length of Operating Panel | 430 | 430 | 430 | 430 | 430 | 430 |

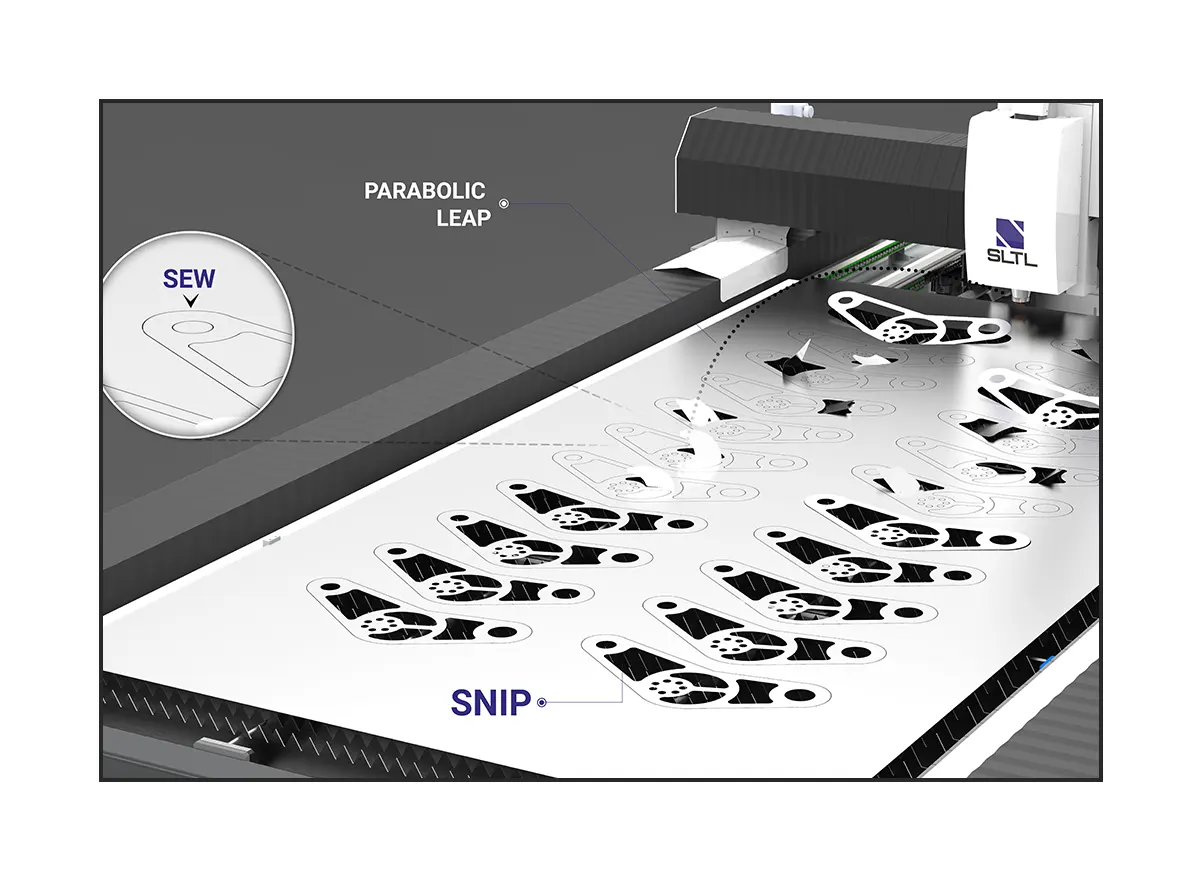

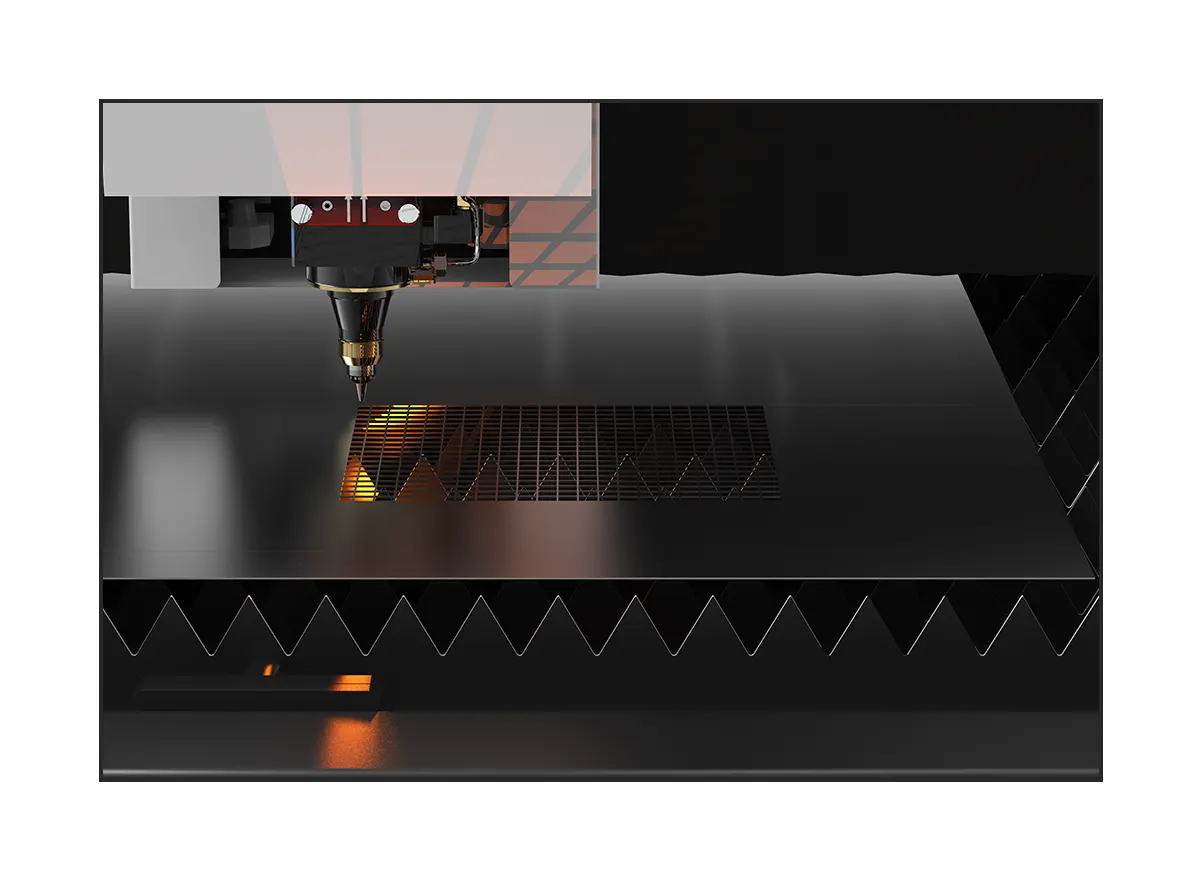

The anti-collision mechanism consists of snip, sew and parabolic leaps, this minimizes non-productive times which can happen due to parts tipping over when cutting thin sheet metal, and ensures that the sheet cut-out pieces do not collide with the laser head while processing and makes your machine permanently productive.

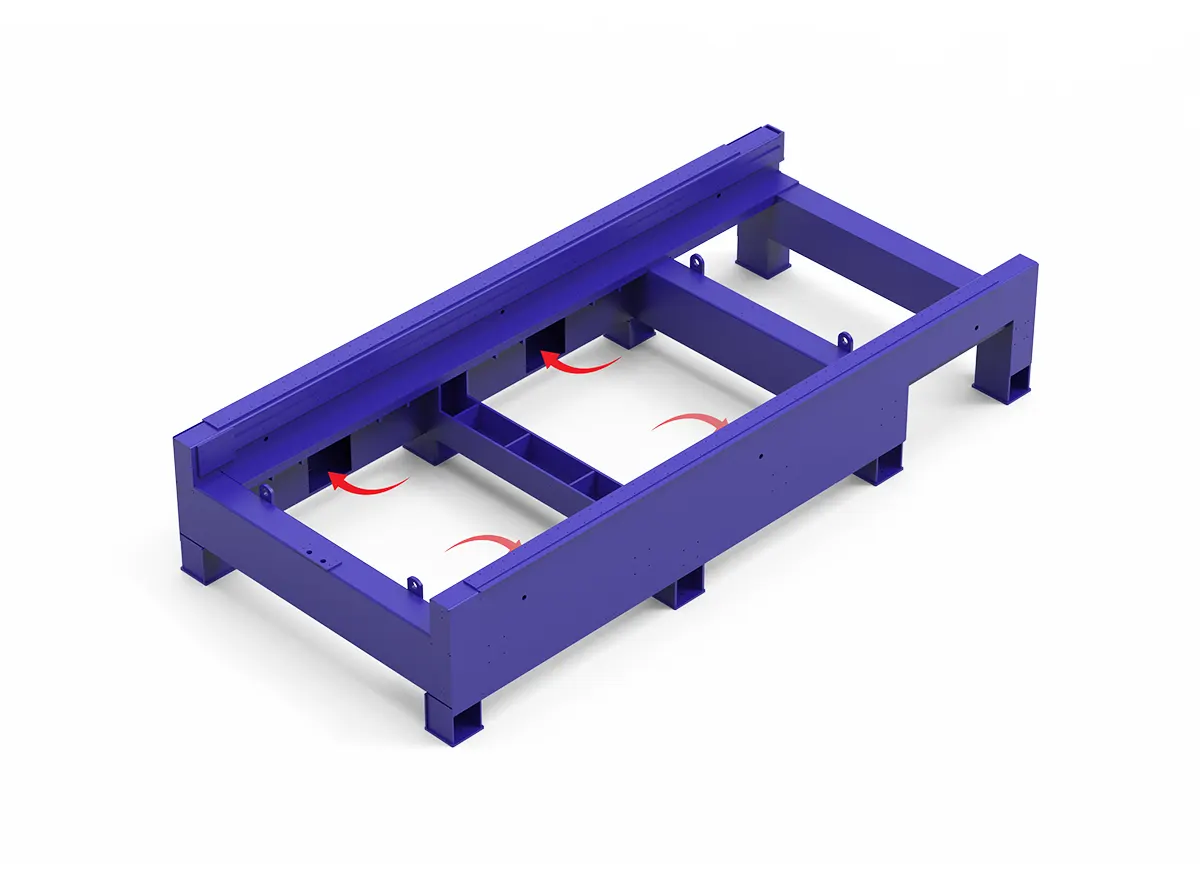

Infinity F1 Fiber Laser Cutting Machines from SLTL include a dynamic fume extraction technology that opens the fume collecting vault of the machine base precisely where the application is being conducted. These fume ducts collect the fumes and send them to the dust collection unit in order to prevent the toxic fumes produced during the metal processing from being released into the environment.

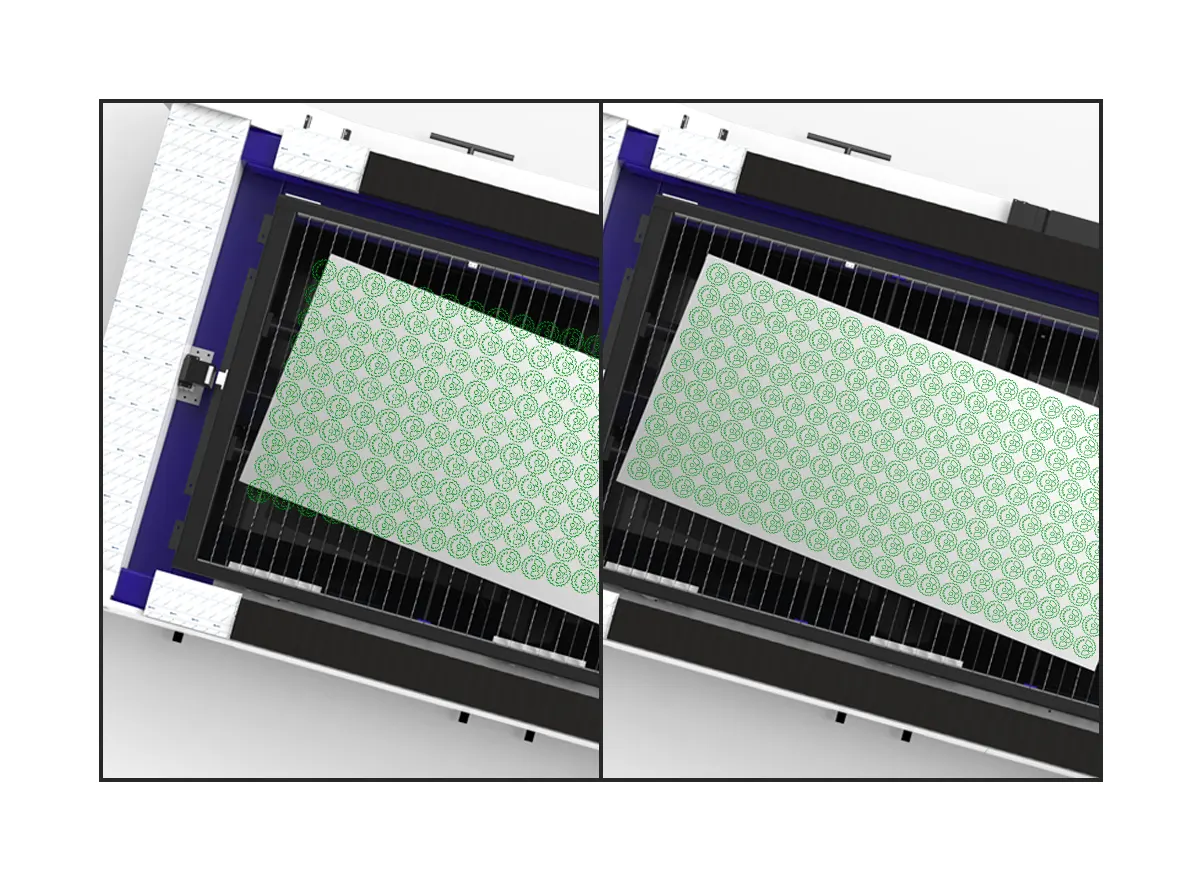

Speed up the cutting process by eliminating the manual alignment of the sheet for each cutting operation. Auto-sheet orientation feature enables automatic orienting of the program to that angle in which the sheet has been kept which ultimately eliminates the non-productive time of rearranging the sheet.

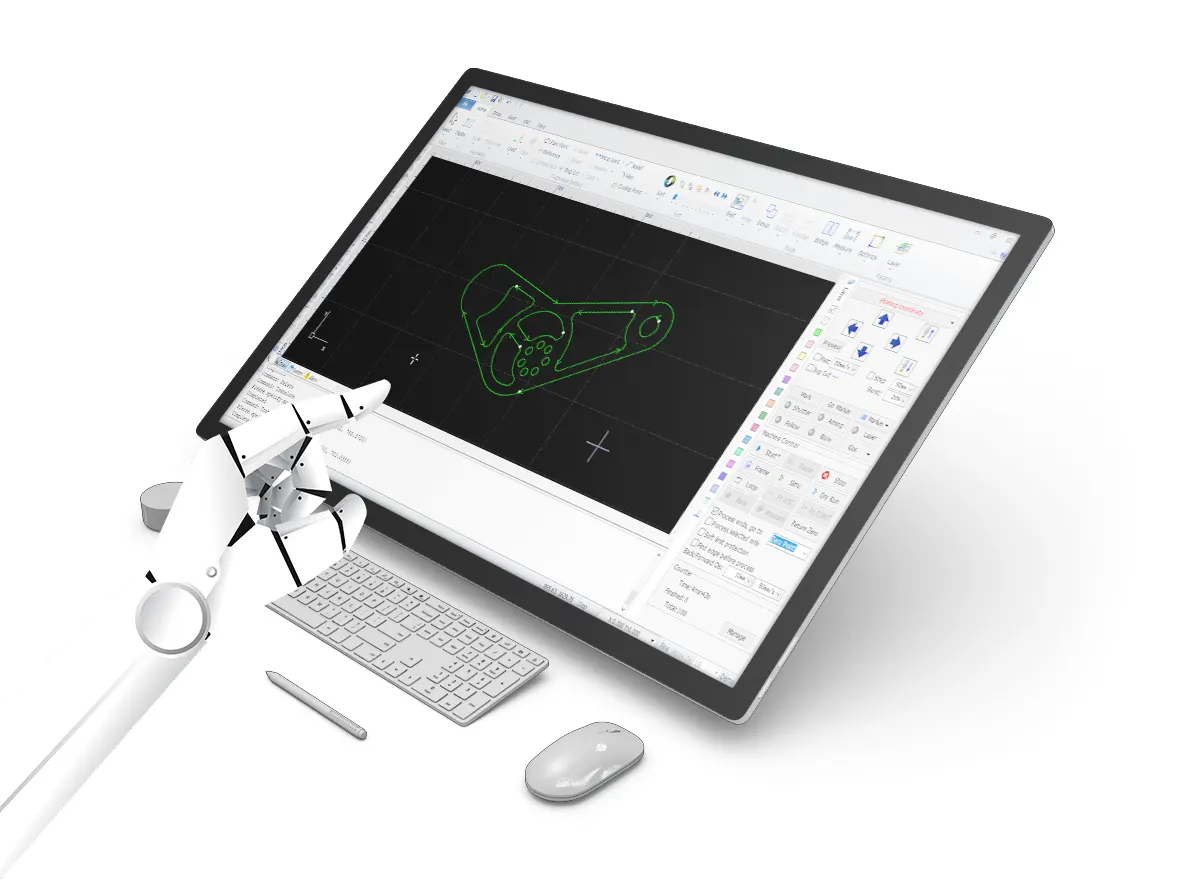

Smart nesting software with a high level of intuitiveness that focuses on reducing processing time not only for the smaller designs but also for the larger parts. The software provides flexibility for users to add, change or delete programs on the go. It helps in achieving maximum precision and high speed with laser outputs of up to 10 kW.

Infinity F1 is equipped with a High-end 64-bit CNC controller along with a user-friendly operating interface. This magnificent controller responds within nanoseconds which makes the machine super responsive. The laser starts at a predetermined point and continues along the course of the line until the shape has been thoroughly cut. It increases productivity by saving time and executing precision finish.

The industry has always appreciated quick and effective working. With a SLTL design two-level swift pallet changer, the productivity boosts by 2X. With the swift pallet changer, the aim of industry for continuous production can be effortlessly achieved.

One of the key features to process high-speed cutting applications in Fiber laser cutting machines, FLYCUT performs the continuous cutting of the desired shape without lifting up the laser head giving a boost to the processing speed by reducing the head travel movements.

The laser head maintains a consistent gap with the material. If in case of varying material properties, through the online software, the laser head could be adjusted, during operation to get the proper cut quality with precision & accuracy.

Superior laser machines are integrated with Smart nesting software having a high level of intuitiveness that focuses on reducing processing time not only for the smaller designs but also for the larger parts. The software provides flexibility for users to add, change or delete programs on the go. It helps in achieving maximum precision and high speed with laser outputs of its peak power.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item

.webp)

.webp)

.webp)

.webp)