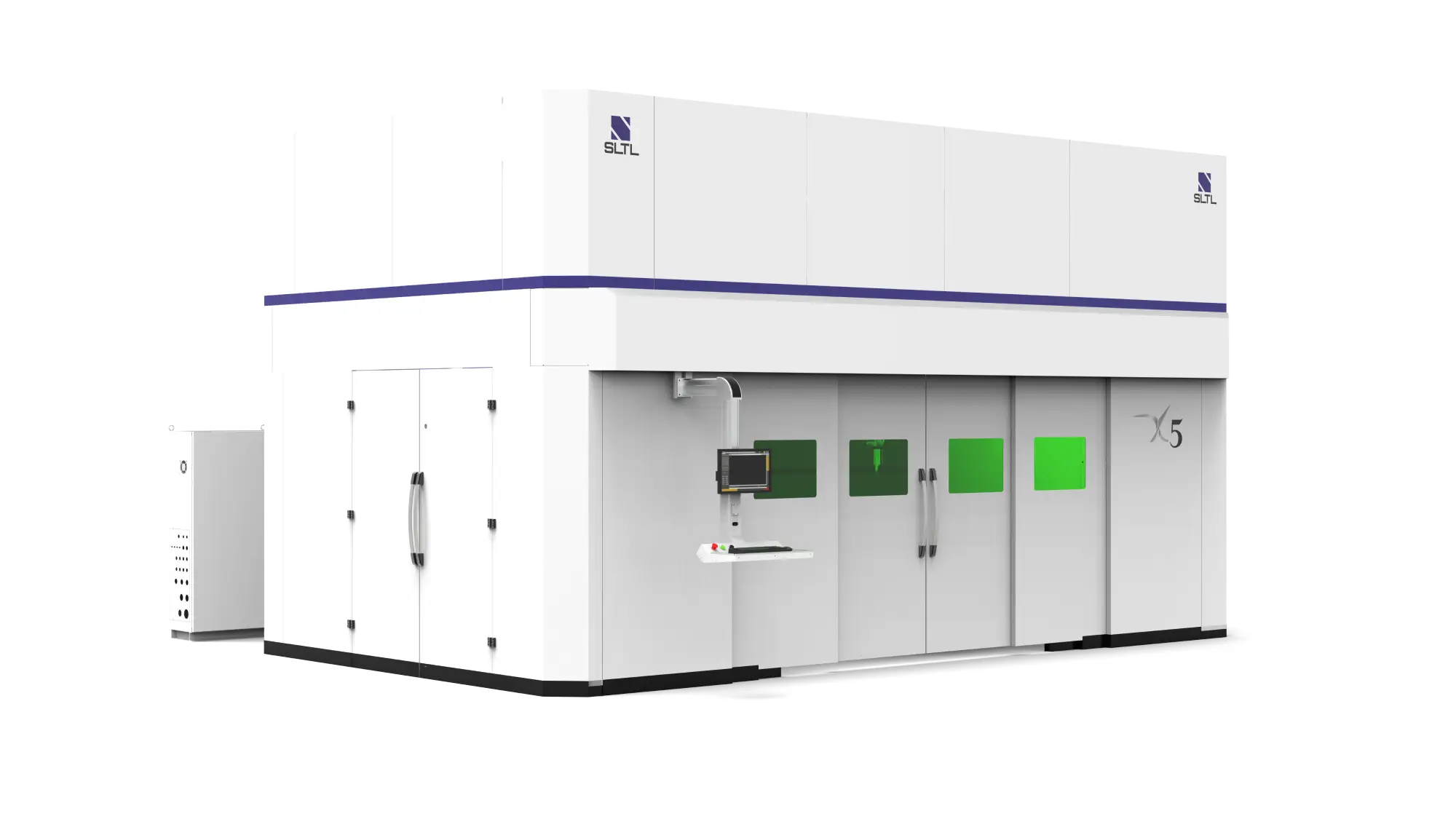

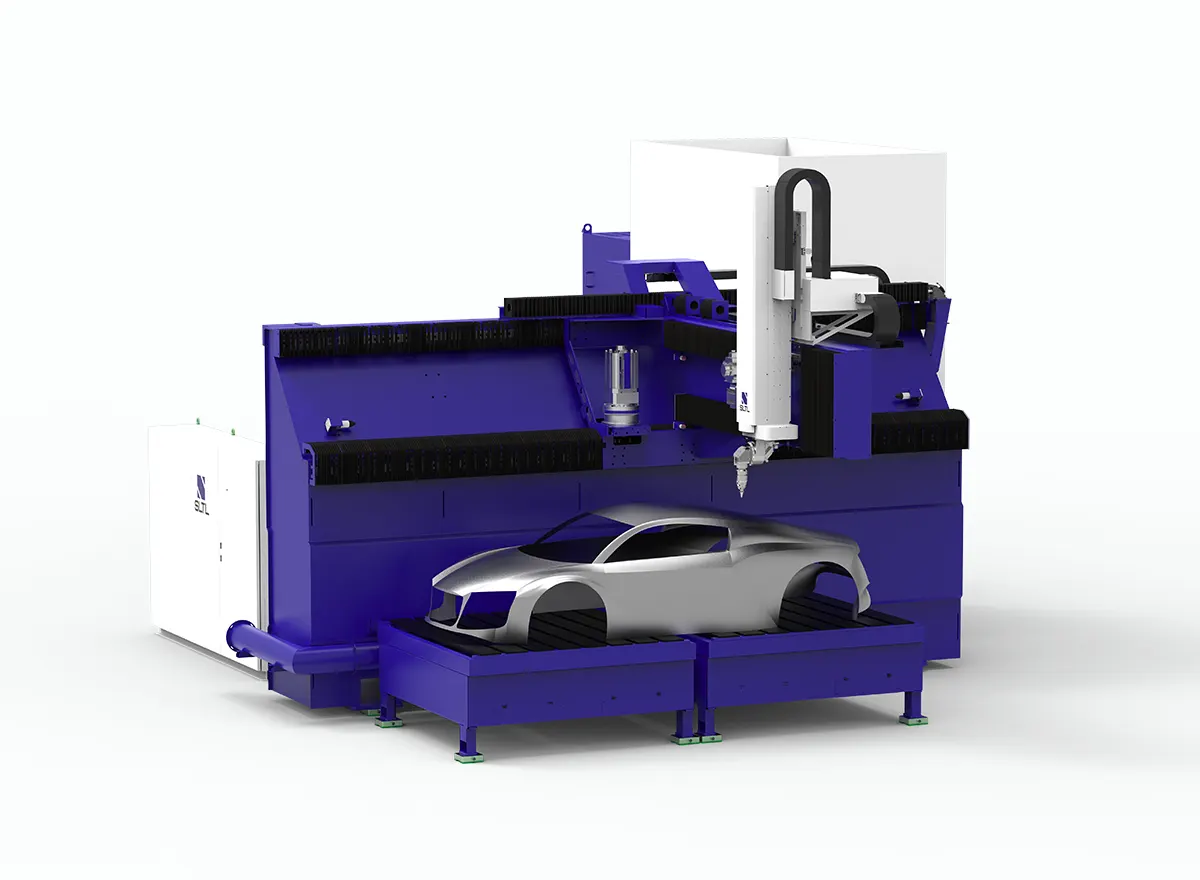

SLTL X5 3D Fiber Laser

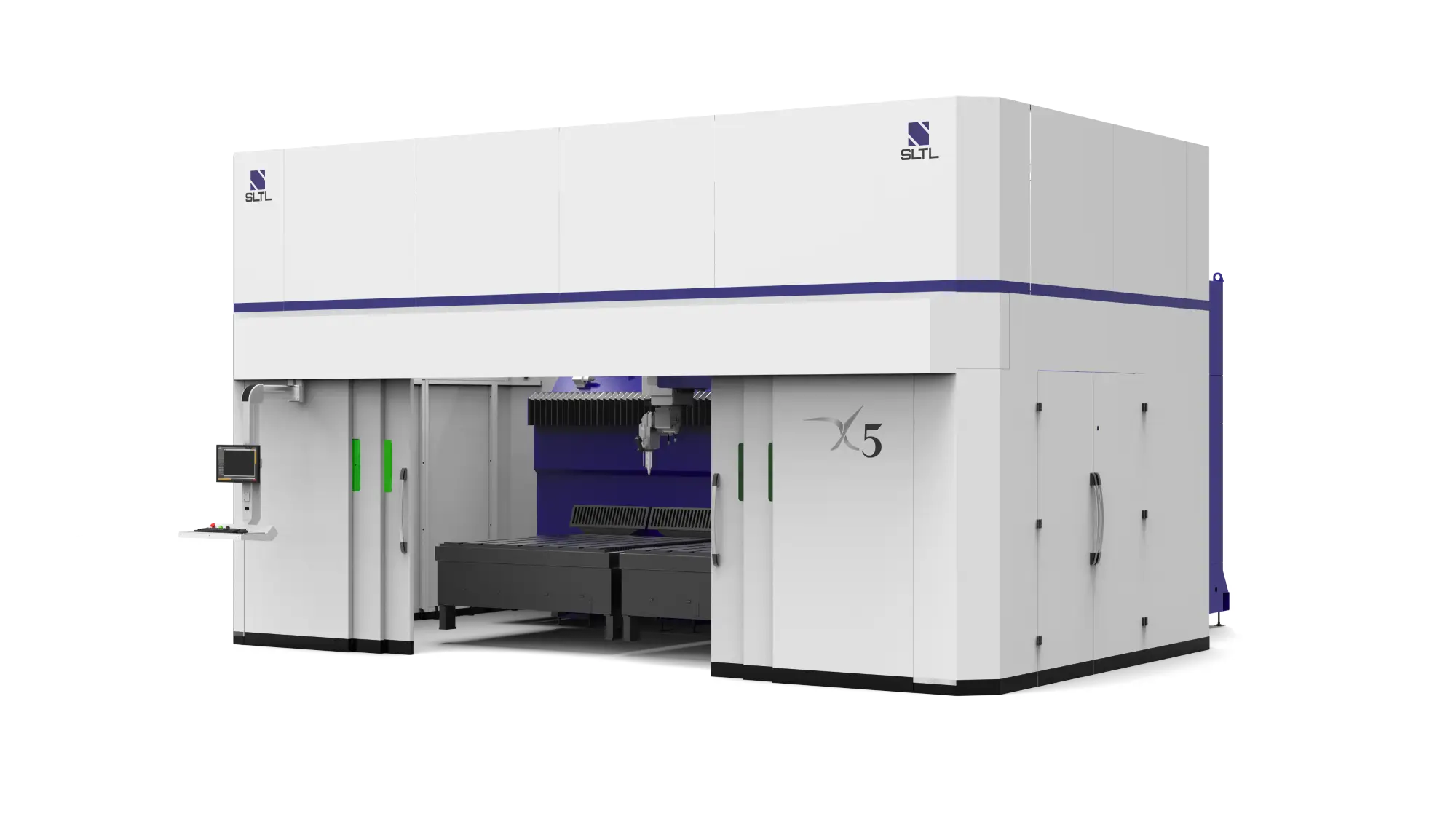

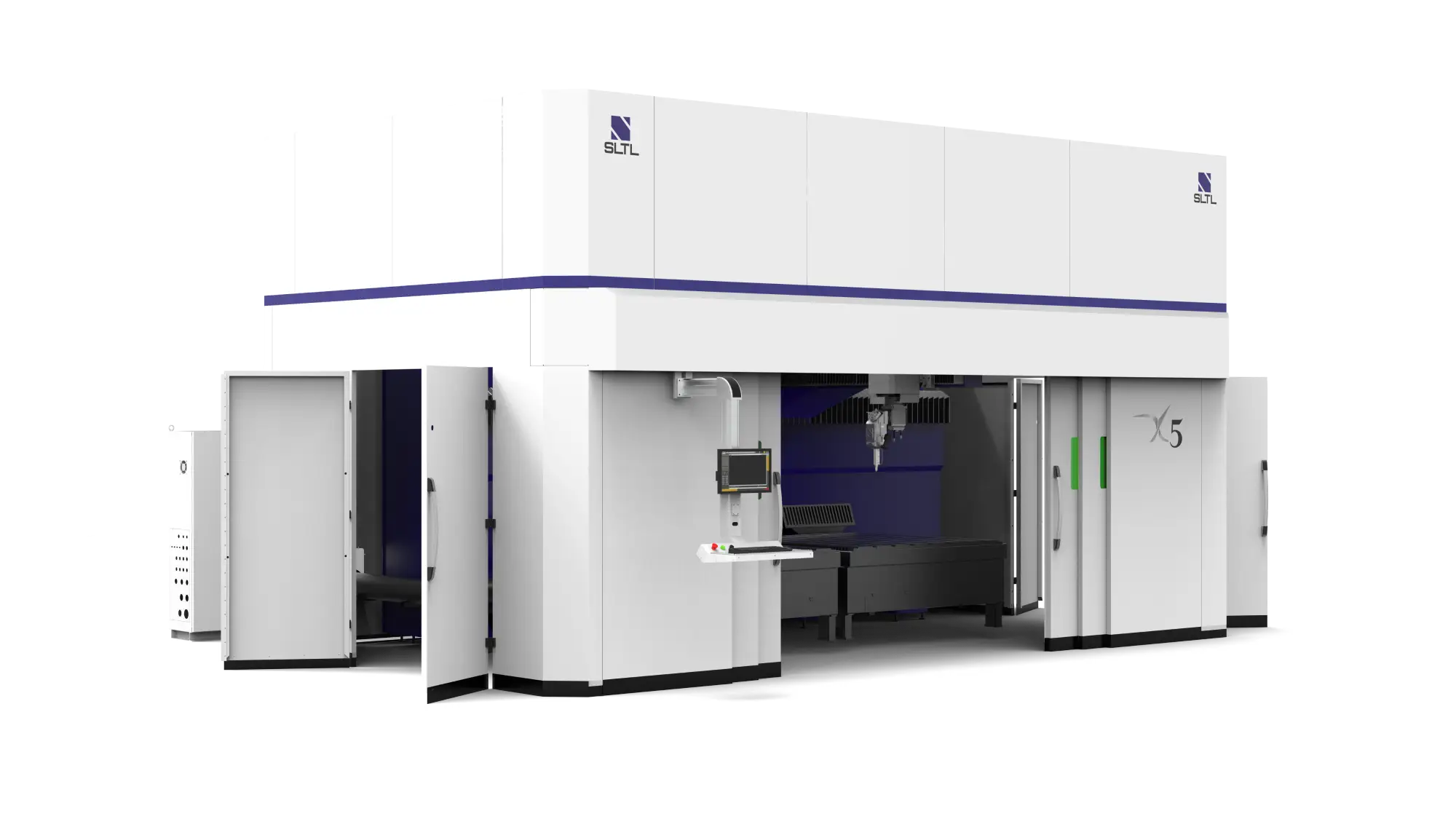

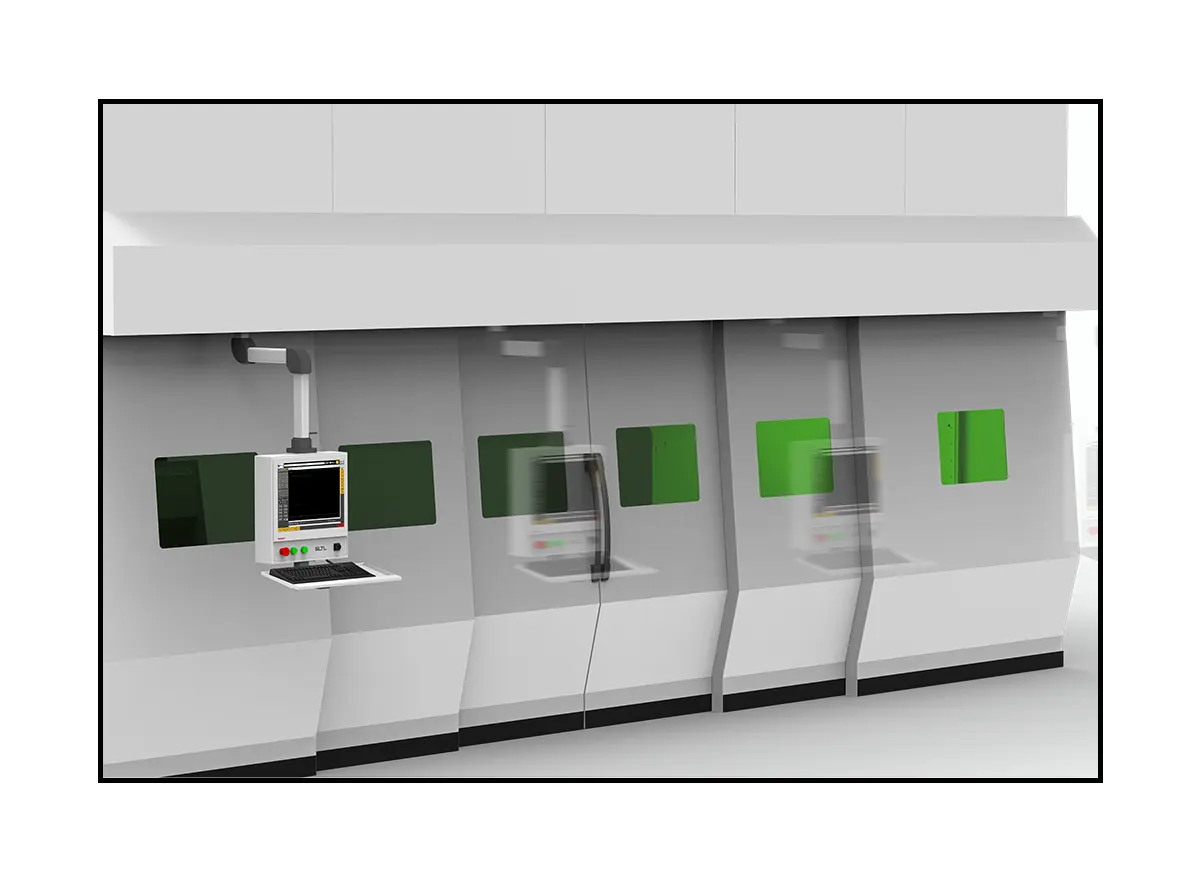

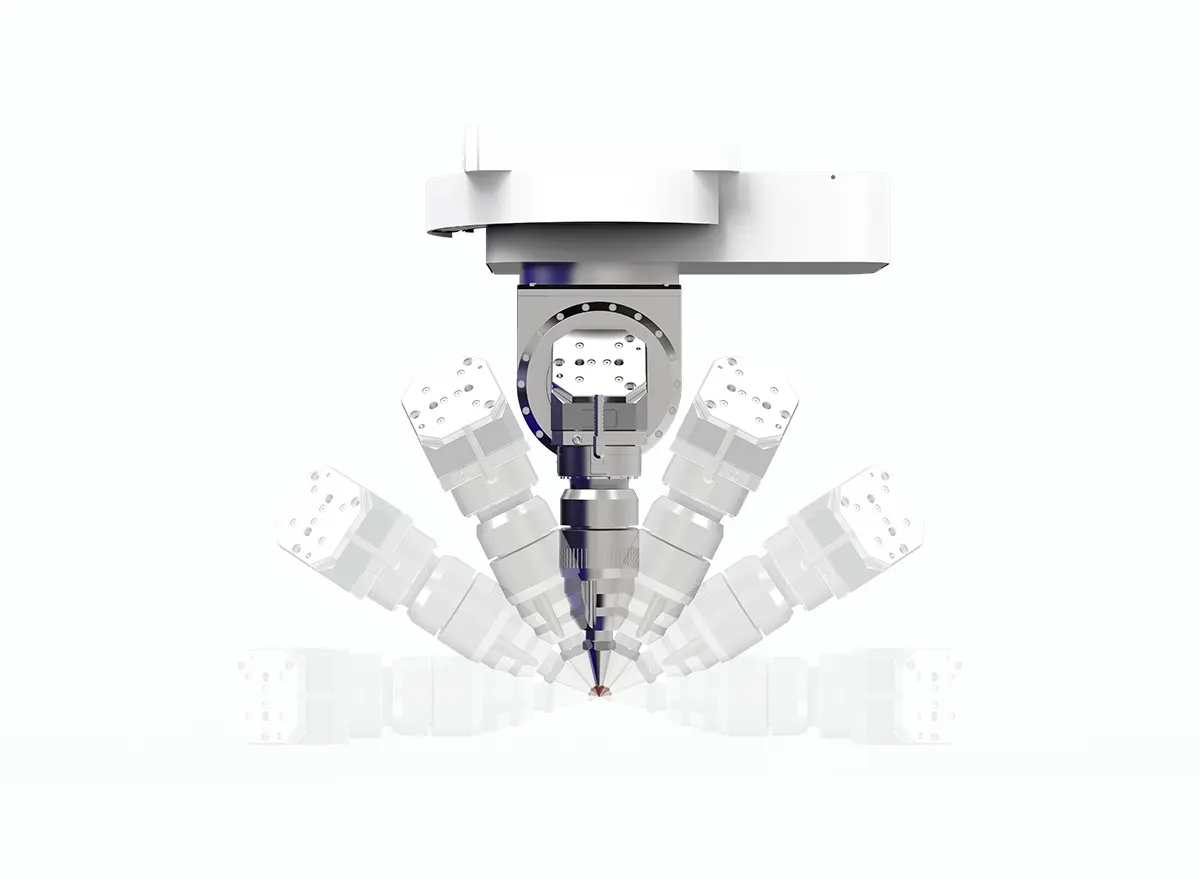

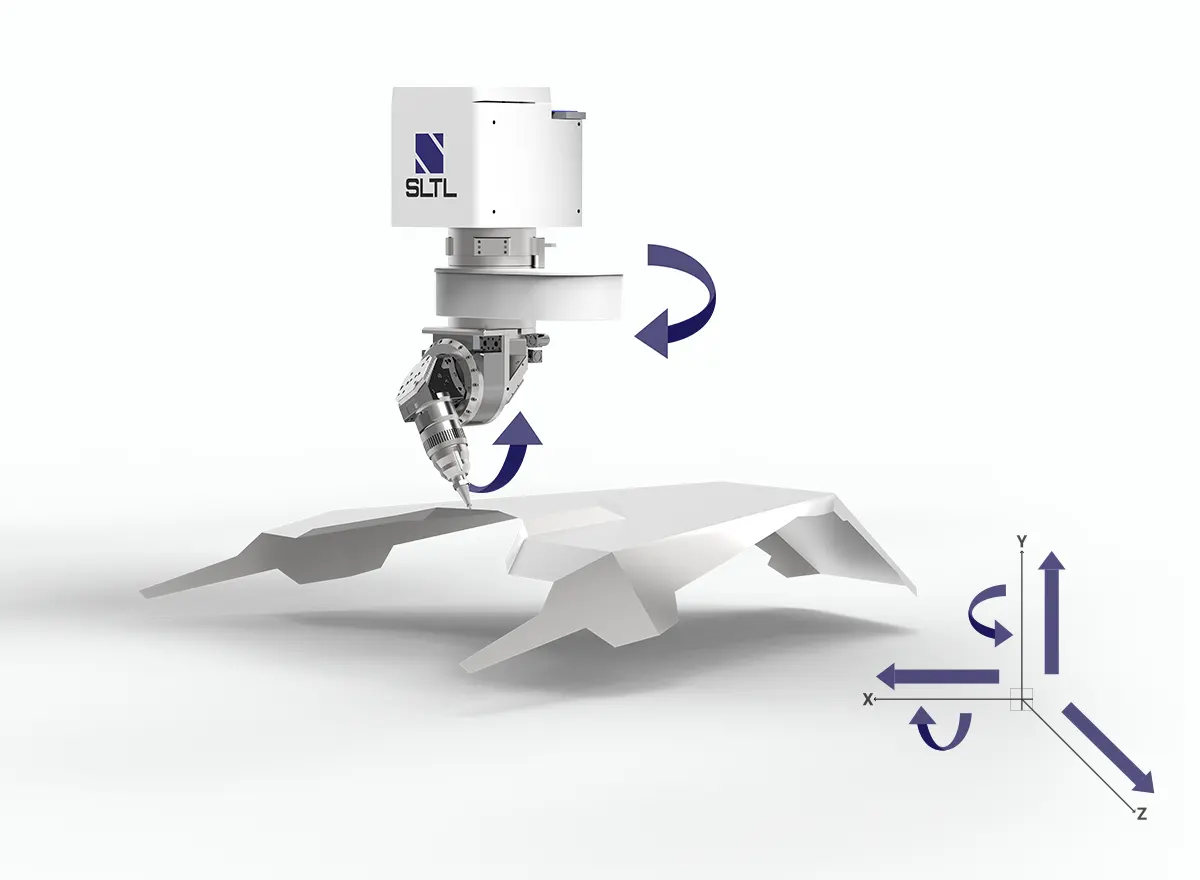

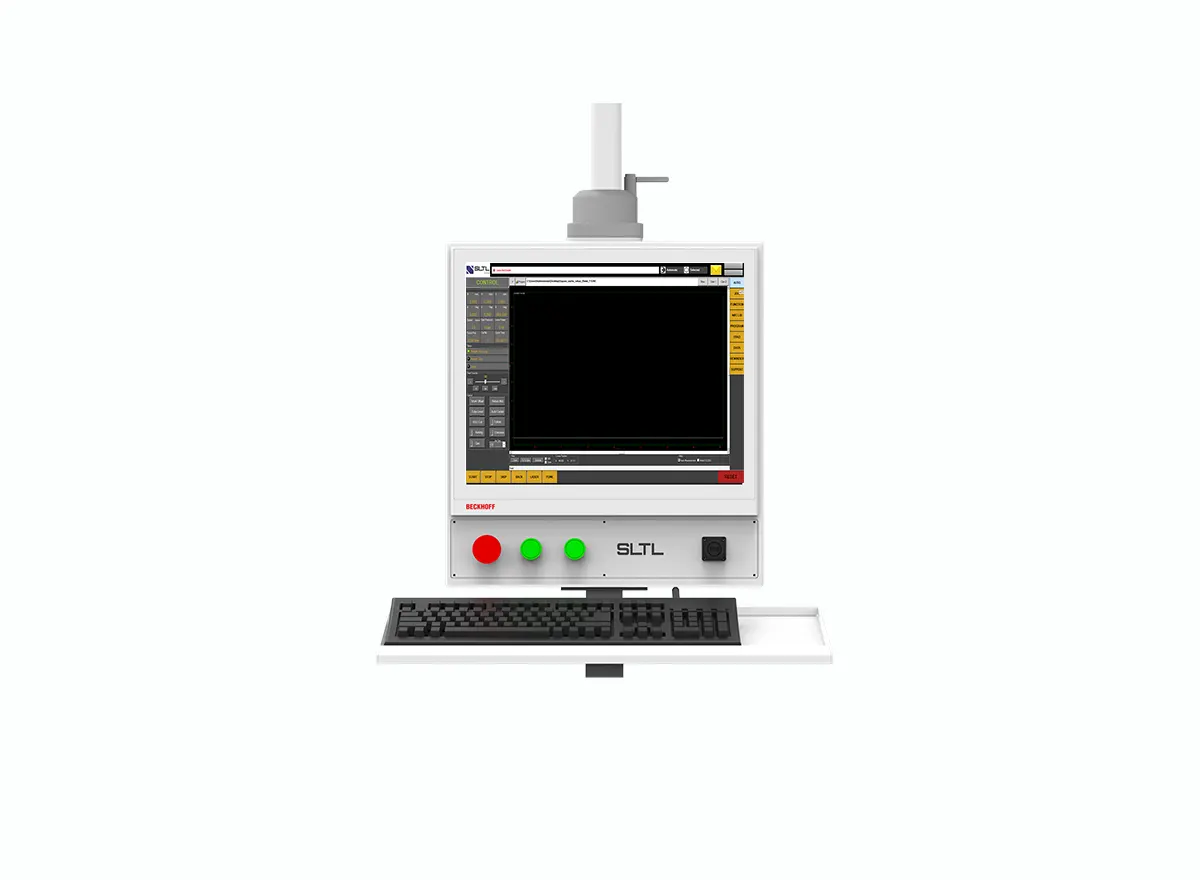

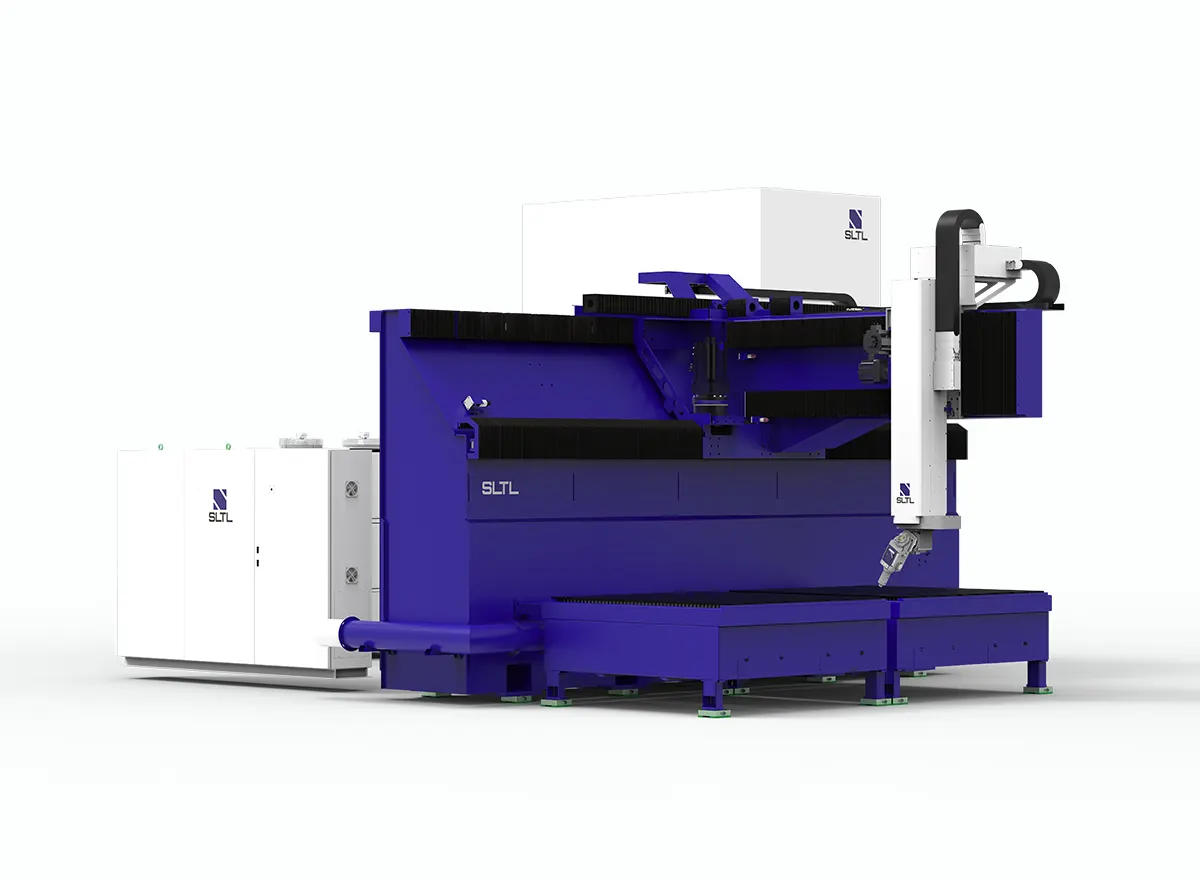

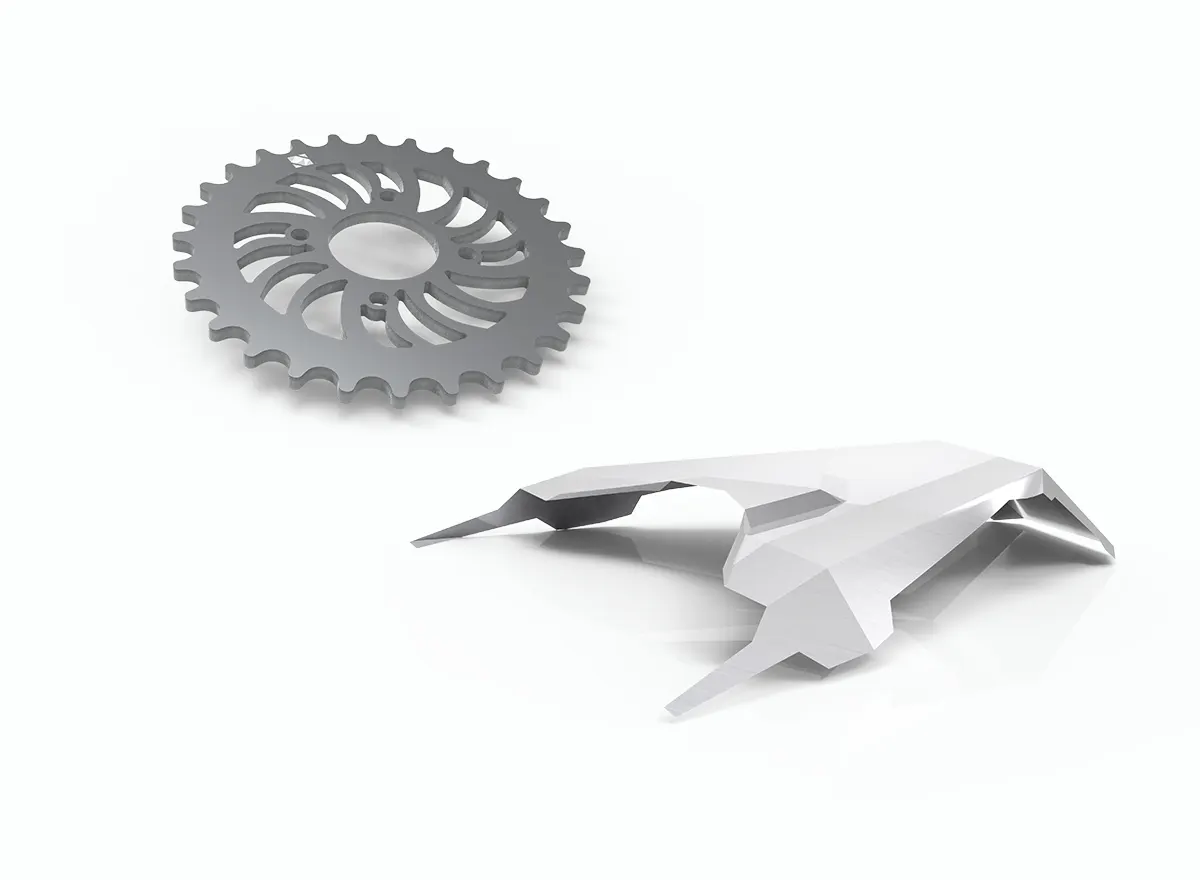

SLTL is the Leading Manufacturer of 3D Laser Cutting systems. The innovation leaders introduced 5 axis laser cutting machine– X5, to address various problems. The futuristic machine is capable of cutting any complex part because of its 5 axis advanced technology. Precisely performing application on Stainless Steel, Mild steel, Aluminium, Brass, Copper & other metals, X5 can reach critical points on the components by adjusting it. The complex cutting task is made easy by just one-time programming which eliminates other systems for component adjustments. This high-power 3D laser cutting machine could rapidly operate over diverse components.

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| X Axis Travel | mm (inch) | 1500 (59.05″) | 2000 (78.74″) |

| Y Axis Travel | mm (inch) | 3000 (118.11″) | 4000 (157.48″) |

| Z Axis Travel | mm (inch) | 650 (25.59″) | 650 (25.59″) |

| C Axis Travel | degree | ± Endless | ± Endless |

| A Axis Travel | degree | ± 135 | ± 135 |

| Work Envelope (3D) | mm | 2550 (100.3″) X 1050 (41.3*) X 650 (25.5″) | 3550 (139.7″) X 1550 (61″) X 650 (25.5″) |

| Maximum Sheet Weight | kg (lb) | ~ 750 (1653) | ~ 1100 (2425) |

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| Maximum Speed X Axis | m/min. (in/min) | 80 (3149.61″) | 80 (3149.61″) |

| Maximum Speed Y Axis | m/min. (in/min) | 80 (3149.61″) | 80 (3149.61″) |

| Maximum Acceleration X Axis | m/s2 | 10 (1G) | 10 (1G) |

| Maximum Acceleration Y Axis | m/s2 | 10 (1G) | 10 (1G) |

| Positional Accuracy | mm/m (in/m) | ± 0.1 (± 0.004″) | ± 0.1 (± 0.004″) |

| Repeatability | mm/m (in/m) | ± 0.05 (± 0.002″) | ± 0.05 (± 0.002″) |

| C & A Axis Accuracy | Arc Second | ± 3 | ± 3 |

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| Rotation Range C Axis | degree | ± Endless | ± Endless |

| Maximum Speed C Axis | degree/sec | 720° | 720° |

| Maximum Acceleration C Axis | degree/s2 | 3600° | 3600° |

| Swivel Range A Axis | degree | ± 135 | ± 135 |

| Maximum Speed A Axis | degree/sec | 720° | 720° |

| Maximum Acceleration A Axis | degree/s2 | 3600° | 3600° |

| Drive Unit C & A Axis | Torque Motor / HG Drives | Torque Motor / HG Drives | |

| Measuring System C & A Axis | Absolute | Absolute | |

| Weight of Head | kg | < 40 | < 40 |

X5 achieves the best-cut quality at a sheer speed to continuously cut 2D or 3D structures in no time for a pre-defined area. The operator can relatively reduce the working time and thus experiences an increasing trend in productivity.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item