SLTL Rapid-G 2D & Tube Fiber Laser

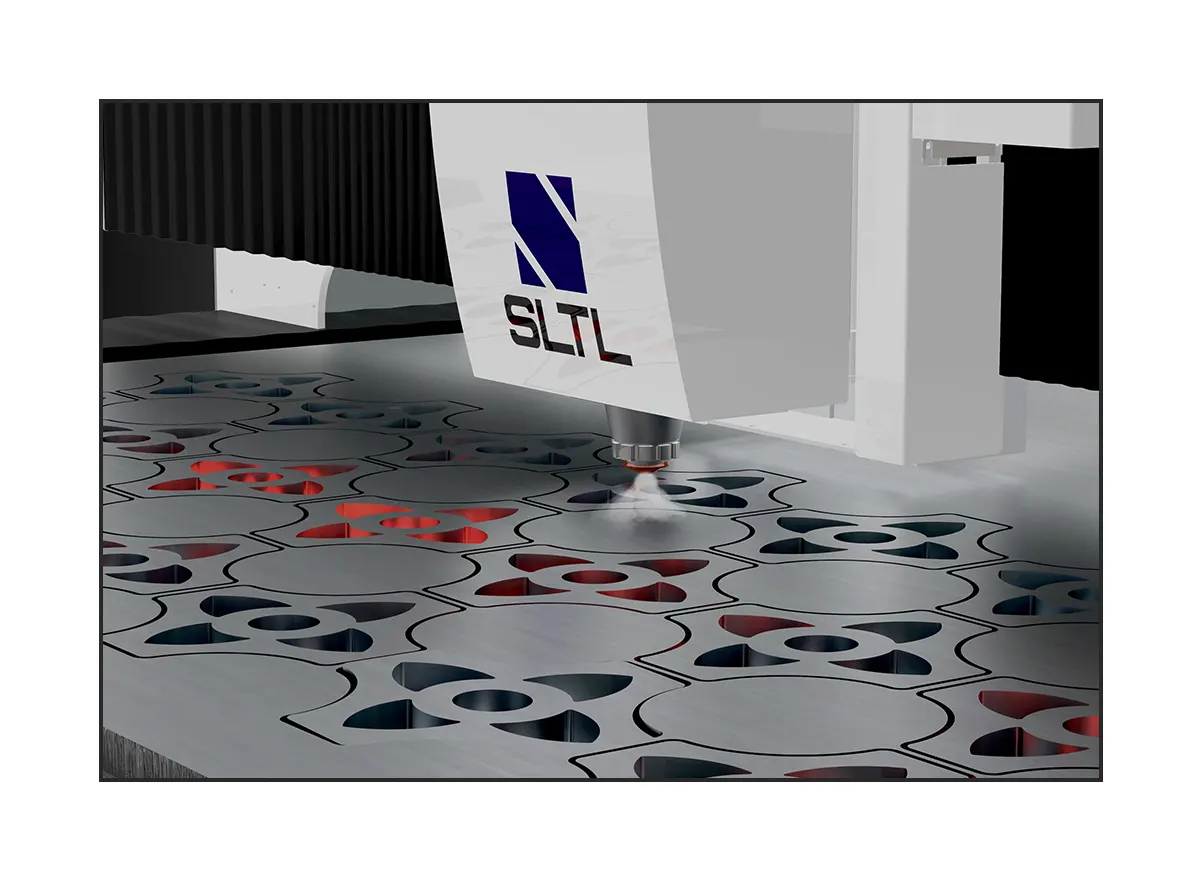

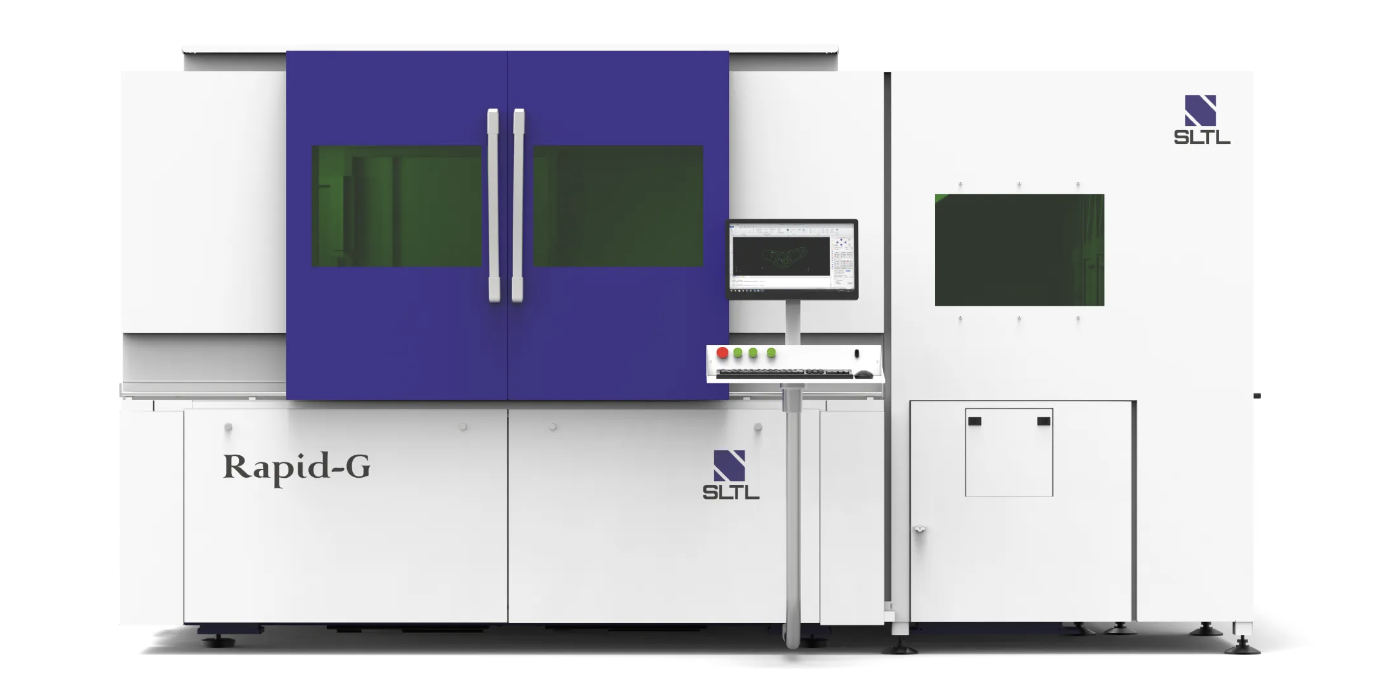

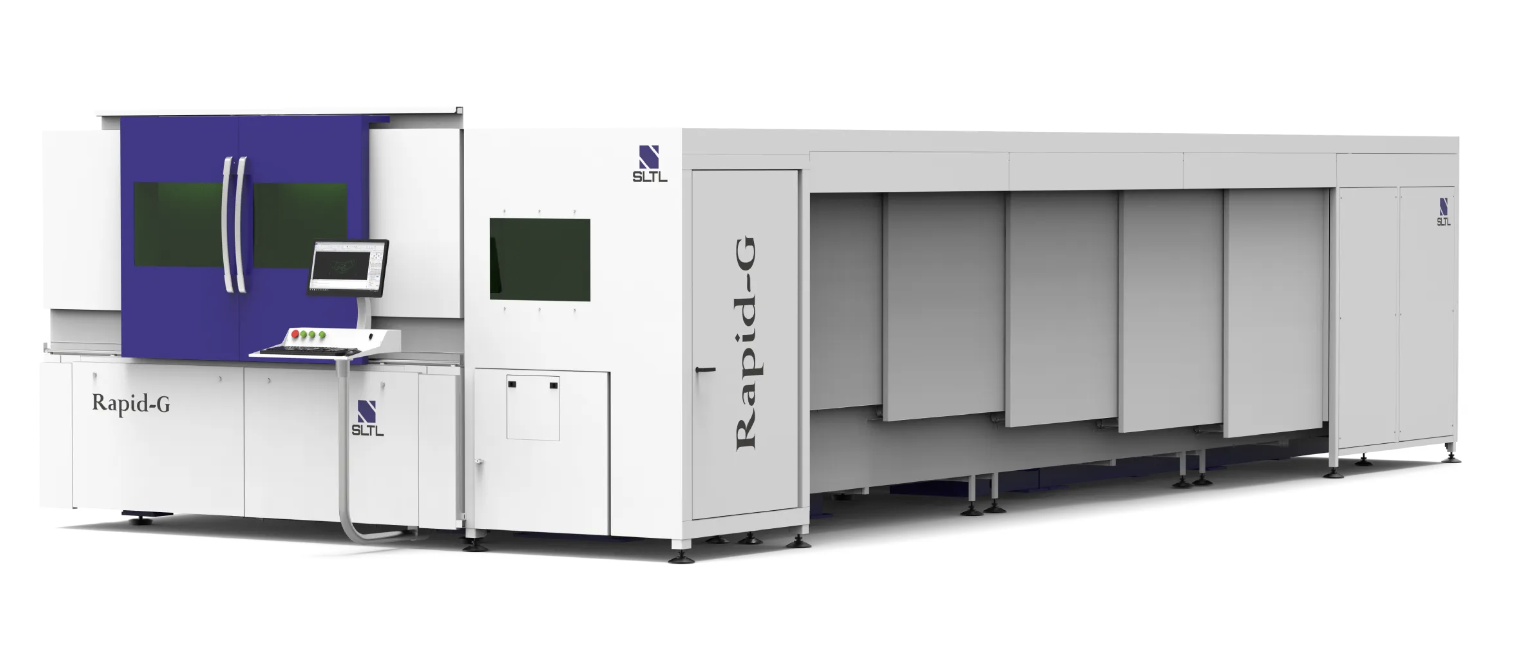

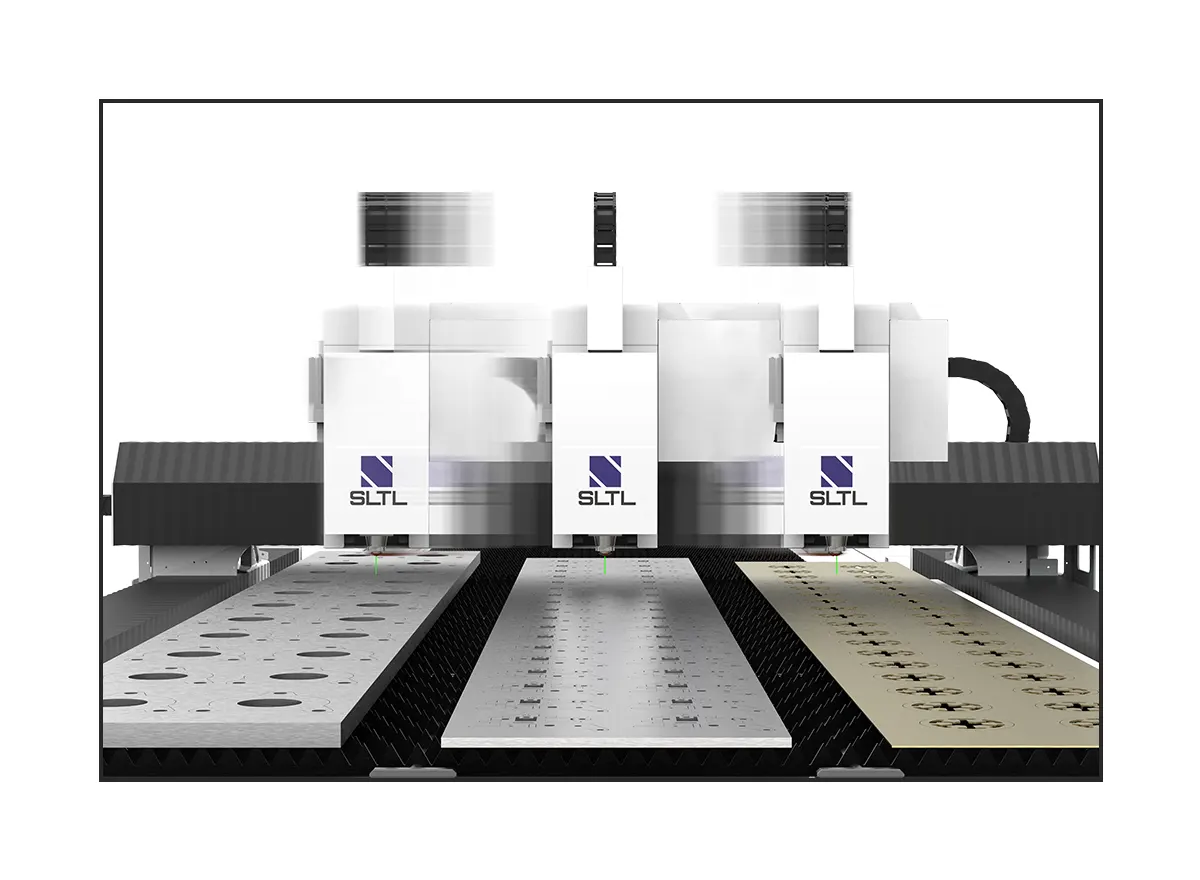

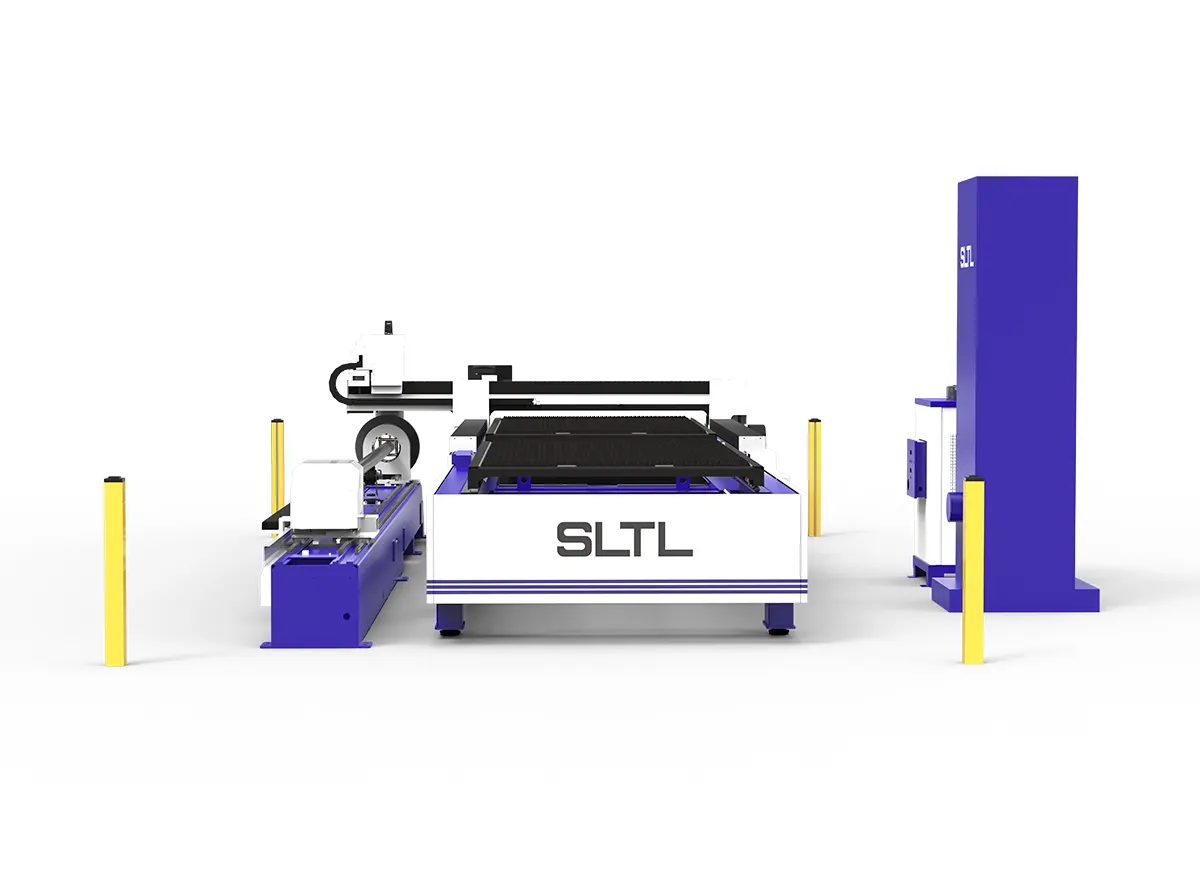

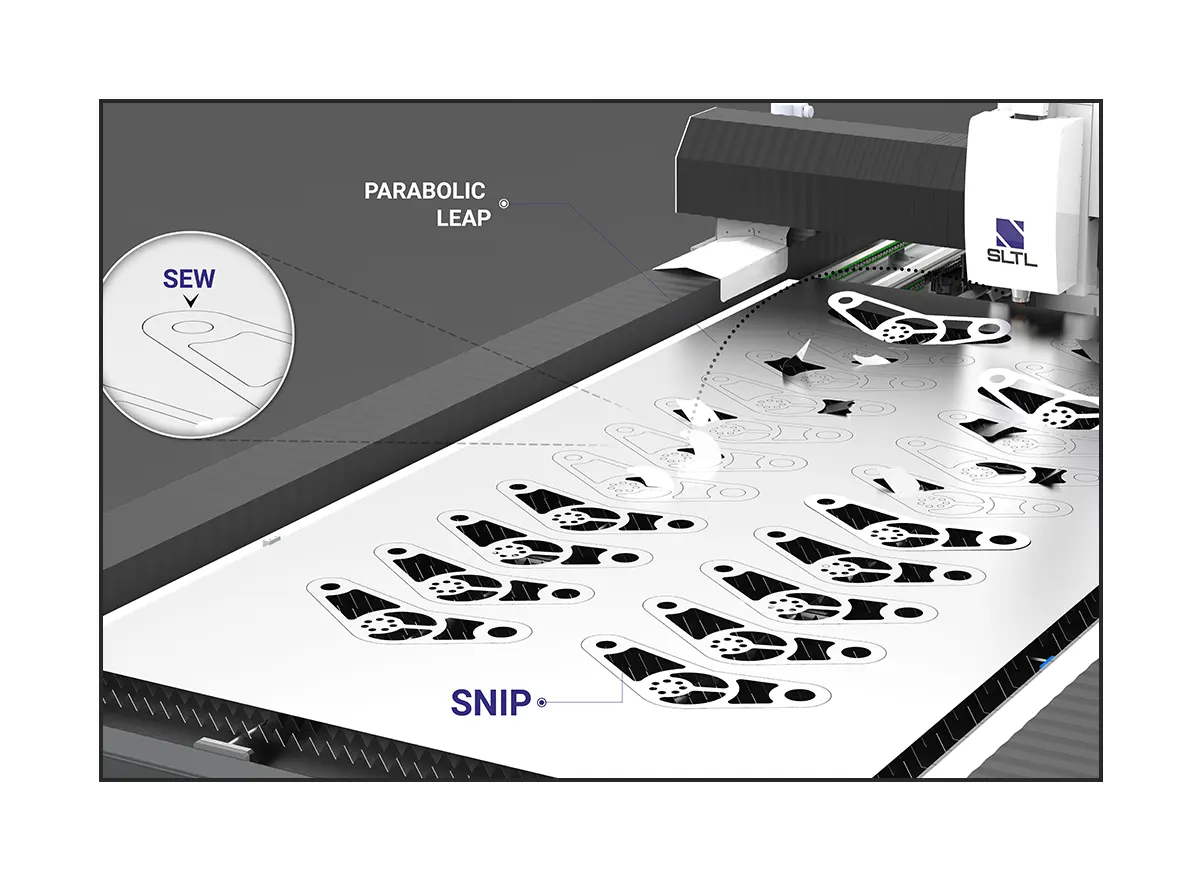

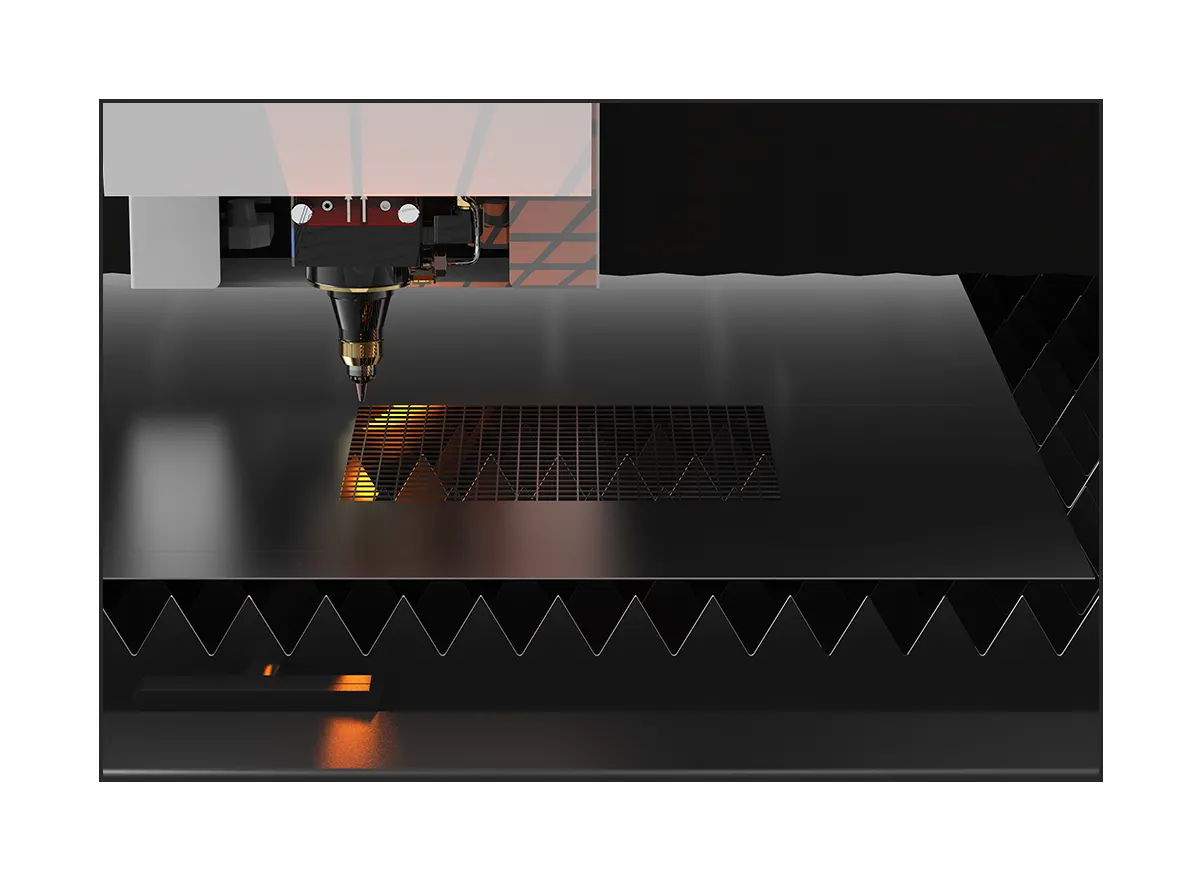

SLTL India’s first fiber laser cutting machine inventor & manufacturer has designed the Rapid-G 2D & Tube Fiber Laser machine. It is known for its extensiveness considering the specific needs of the metal cutting industry. Designed based on modular product architecture, it is integrated with a rotary attachment allowing the processing of sheets as well as tubes on a single system. A few more fascinating features are common cut, single lens mechanism, ball support sheet loading, and dynamic fume extractor mechanism, putting all these features together, the machine becomes a must-buy for sheet metal cutting works. A High-end 64-bit CNC controller is equipped with a user-friendly operating interface. The magnificent controller responds within 20 nanoseconds which makes the Infinity super responsive.

| Unit | Working Range 2D | ||

|---|---|---|---|

| 3015 | |||

| Maximum Working Range | X Axis | mm | 1550 |

| Y Axis | mm | 3100 | |

| Z Axis | mm | 300 | |

| Maximum Workpiece Weight | kgs | 900 | |

| Positioning Precision | mm/meter | ±0.05 | |

| Repeatability | mm/meter | ±0.02 |

| Unit | 3m | 6m | 7.6 | ||

|---|---|---|---|---|---|

| Maximum Working Range | X | mm | 150 | 150 | 150 |

| Y | mm | 2950 | 5950 | 7550 | |

| Z | mm | 300 | 300 | 300 | |

| Maximum Pipe size | Round | mm | 25 to 180 | 25 to 180 | 25 to 180 |

| Square | mm | 25 to 180 | 25 to 180 | 25 to 180 | |

| Rectangular | mm | 25 to 180 | 25 to 180 | 25 to 180 | |

| Maximum Workpiece Weight | kgs | 140 | 140 | 140 | |

| Maximum Pipe Cutting Length | mm | 2500 | 5500 | 7100 | |

| 4 Jaw Chuck Dia. (Feeding Chuck) | Size | mm | 200 | 200 | 200 |

| Laser Power | 1 kW | 1.5 kW | 2 kW | 3 kW | 4 kW | 6 kW |

|---|---|---|---|---|---|---|

| Mild Steel (MS) (O) | 10 (3/8″) | 12 (1/2”) | 16 (5/8”) | 20 (3/4”) | 22 (7/8″) | 25 (1”) |

| Mild Steel (MS) (N2/Air) | 3 (1/8″) | 4 (3/16″) | 5 (3/16″) | 6 (1/4″) | 6 (1/4″) | 8 (5/16”) |

| Stainless Steel (SS) (O₂) | 6 (1/4″) | 6 (1/4”) | 10 (3/8”) | 10 (3/8”) | 10 (3/8”) | 10 (3/8”) |

| Stainless Steel (SS) (N₂) | 3 (1/8″) | 4 (3/16”) | 5 (3/16”) | 8 (5/16”) | 10 (3/8”) | 16 (5/8”)* |

| Aluminum (Al) | 2 (1/16”)** | 3 (1/8”) | 5 (3/16”) | 8 (5/16”) | 10 (3/8”) | 16 (5/8”)* |

| Brass (Br) | 3 (1/8″)** | 3 (1/8”) | 5 (3/16”) | 6 (1/4”) | 8 (5/16”) | 12 (1/2”) |

| Copper (Cu) | 2 (1/16”)** | 2 (1/16”) | 3 (1/8”) | 5 (3/16”) | 6 (1/4”) | 8 (5/16”) |

| Galvanized Iron (GI) | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* |

| Power Consumption*** | 10 kW | 12 kW | 17 kW | 20 kW | 24 kW | 32 kW |

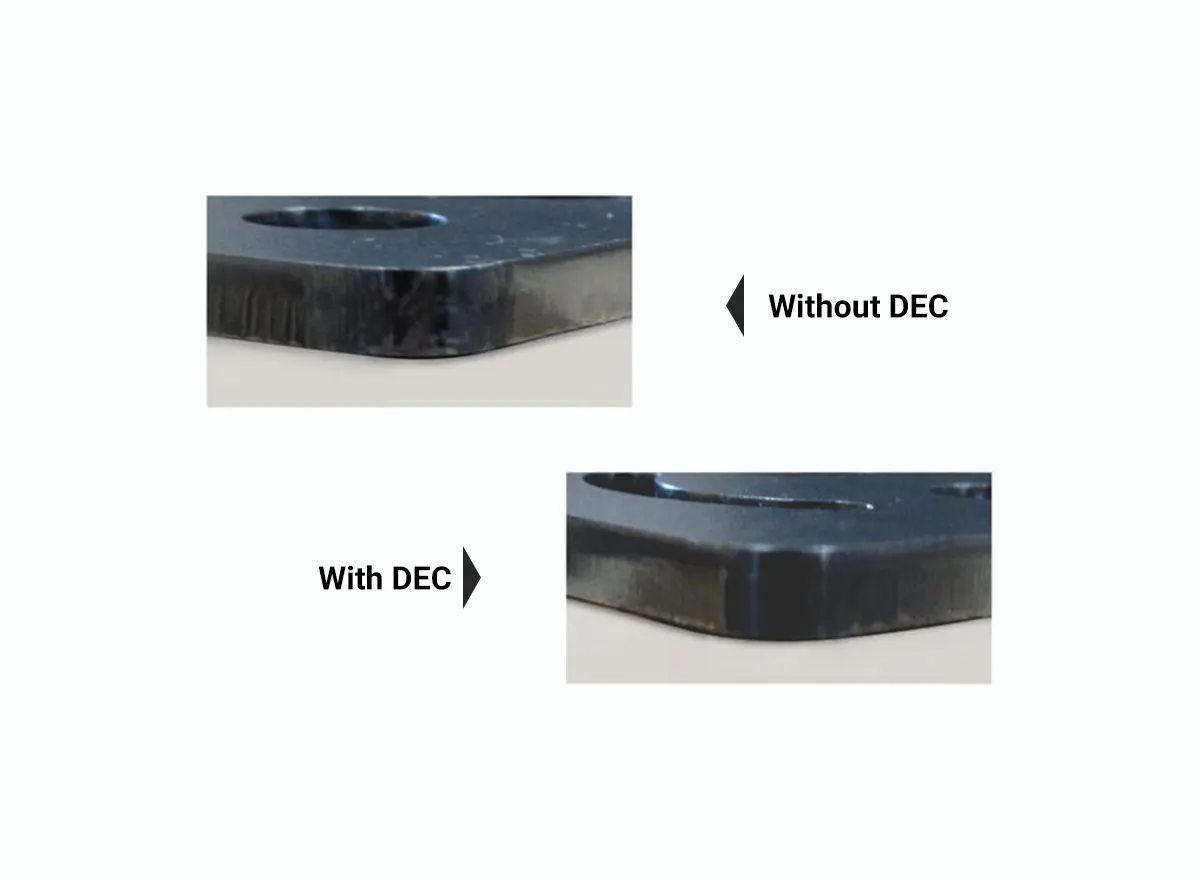

To minimize melting of sharp edges while cutting thicker materials, a cooling point has been specified for a set time period. Here, the assist gas will be turned on continuously, and the laser will be turned off for the stated time period.