SLTL Hertz Handheld Laser Welding

The high-power handheld laser welding system combines the fundamental qualities of an ultra-portable device with uncompromising performance. Designed in new formats, the product’s overall volume is reduced dramatically resulting in an extremely productive and powerful system. This device is a perfect integration of SLTL Group’s Laser Welding Technology and reliable portable structure. The System is a fit for welding complex components as well as large and small components with unmatched strength.

| Laser Power | Upto 2 kW |

|---|---|

| Wave Length | 1080 nm |

| Mode of Operation | Continuous wave (CW) |

| Wall – Plug Efficiency | > 30% |

| Out Power Turning Range | 10 – 100% |

| Emission Modulation upto | 5 kHz |

| Overall Size | 1180 × 665 × 1100 mm |

| Operation Voltage | 1 phase (A.C) (230v – 50Hz) |

| Optional | Wire Feeder, Wobbling Head |

Portability With Performance

Hertz is a power-packed system with a compact structure ready to move around your work floor. Specifically created to reach the complex parts or spaces of the components which can’t be taken to the machine. The flexible machine is designed in a portable framework to provide strong welding joints to different materials.

Eliminate Consumables

Hertz allows operation without any additives or consumables to the welding process. The high-quality welding seam with powerful weld joints can be aesthetically achieved without adding consumables to the laser welding applications.

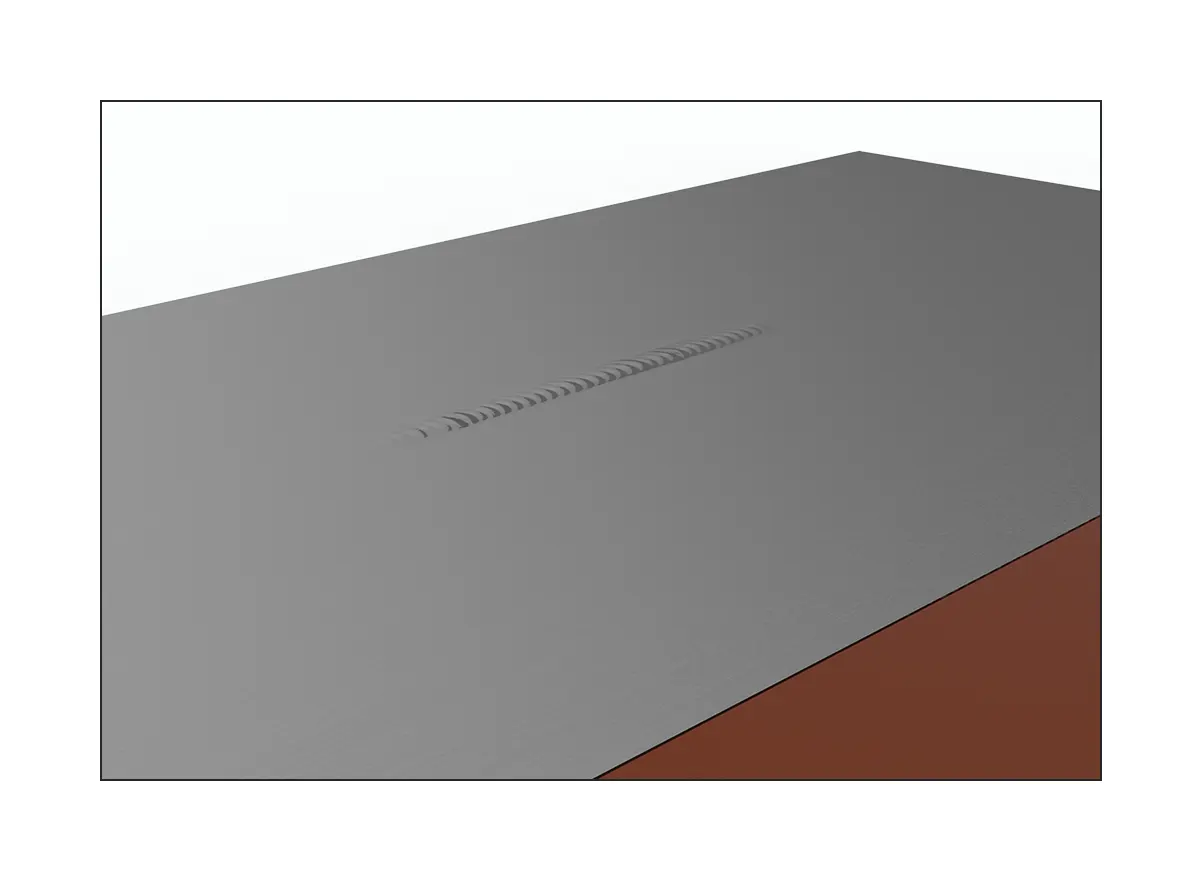

High-Quality Welding Seam

The welding seam is smooth, with negligible distortion allowing users to save time on polishing. A flexible welding machine supports different welding joint types which ensure the precise welding of different materials with the suitability to perform bi-metal welding, joining complex shapes and contours.

Superior Weld Strength

Laser Welding provides stronger weld joint strength than traditional welding methods. The portability of Hertz allows the machine to flexibly create strong welding joints on components of different shapes and sizes.

Eliminate Material Deformation

With hertz forget the deformation of the components, as the HAZ area (Heat-affected zone) is very small to keep the physical structure of the materials intact. Not just this, this robust machine is best suited for consistent weld quality for a longer period of time.

Velocious Welding

The welding can be done in a quicker time, compared to all the conventional welding methods which ultimately increases the production on a mass level in a lesser time.

Reduced HAZ

The HAZ (heat-affected zone) with fiber laser welding is too less compared to all the available welding solutions in the market now.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item