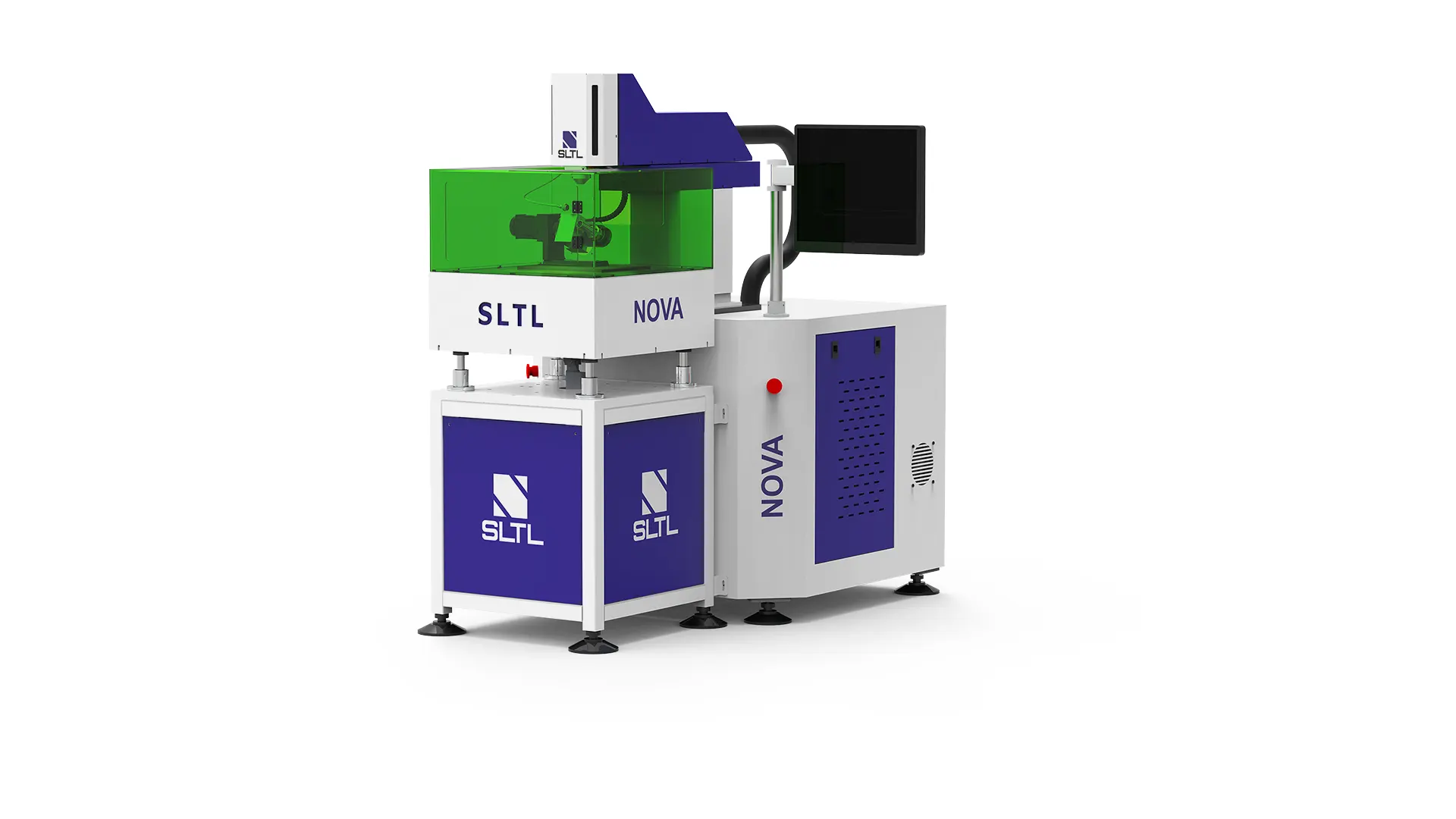

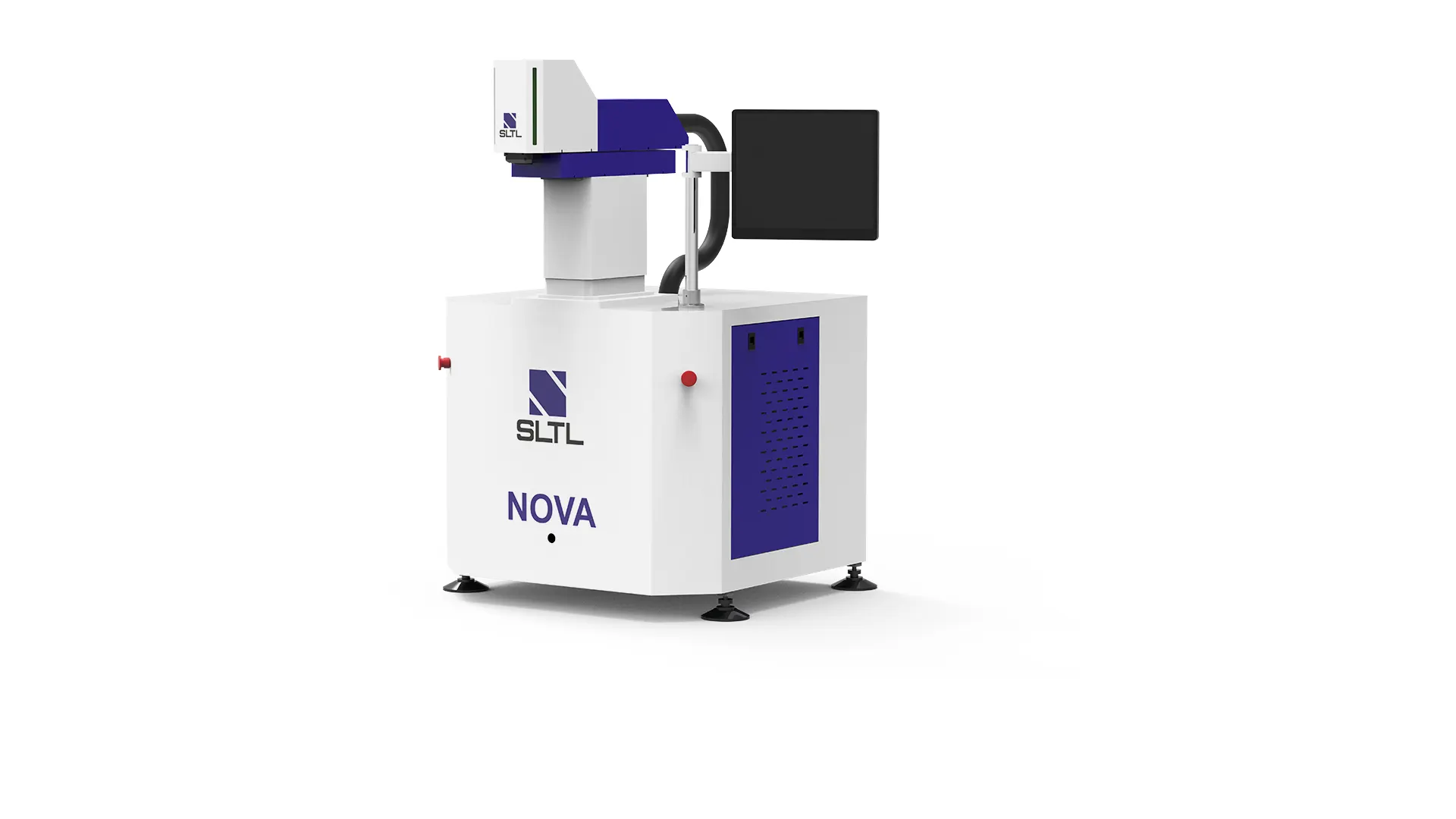

SLTL Nova Laser Welding Machine

With fast welding speed, high efficiency, small heat affected zone, high melting temperatures, high heat conductivity and strong welding joints, the high-power laser welding machine NOVA from SLTL has become an important piece of equipment to meet industrial laser welding requirements. NOVA is designed to give consistent strength and precision which not only enhances the quality and life of the material welded but gives visually flawless seams. One of its kind laser welding automation system, it can be integrated with jigs and fixtures to enhance productivity. For years SLTL has given the best Laser welding solutions for many Industries like Automotive, Medical, Tubes and Pipes, and Jewelery. SLTL Laser Welding Machine not only develops superior welding machines but also provides suitable welding application solutions customized for customers.

| Technical Specifications | |

|---|---|

| Y Axis | 200 mm |

| Z Axis | 200 mm |

| Wavelength | 1070 nm |

| Mode Of Operation | Pulsed / Continuous-Wave (CW) |

| Pulse Duration | 0.05-50 ms |

| Wall-Plug Efficiency | >30% |

| Overall size (L x W x H) | 1240 × 795 × 1520 mm |

| Average Power (W) / Pear Power | 150 / 1500 | 300 / 3000 | 600 / 6000 | 900 / 9000 | 1200 / 12000 |

| Maximum Pulse Energy (J) | 15 | 30 | 45 | 90 | 120 |

Features and Benefits

- this is a list item

- this is a list item

- this is a list item