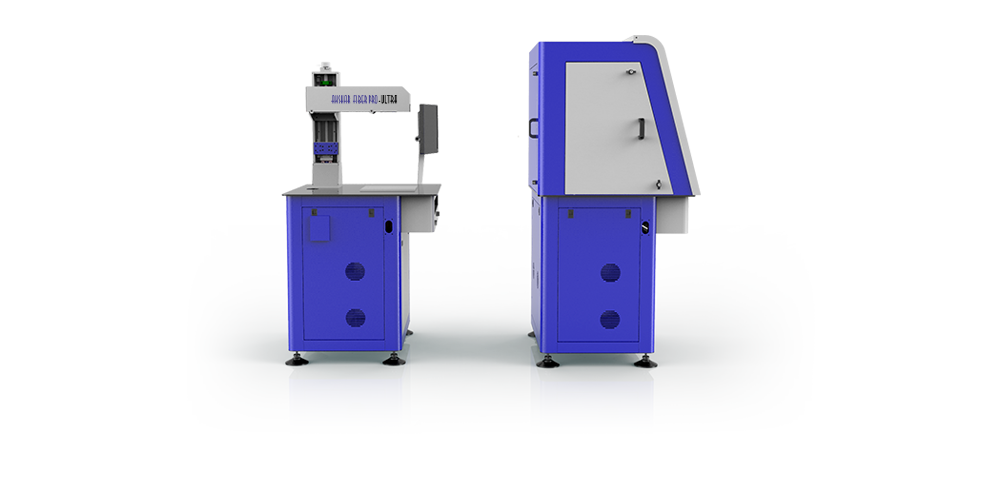

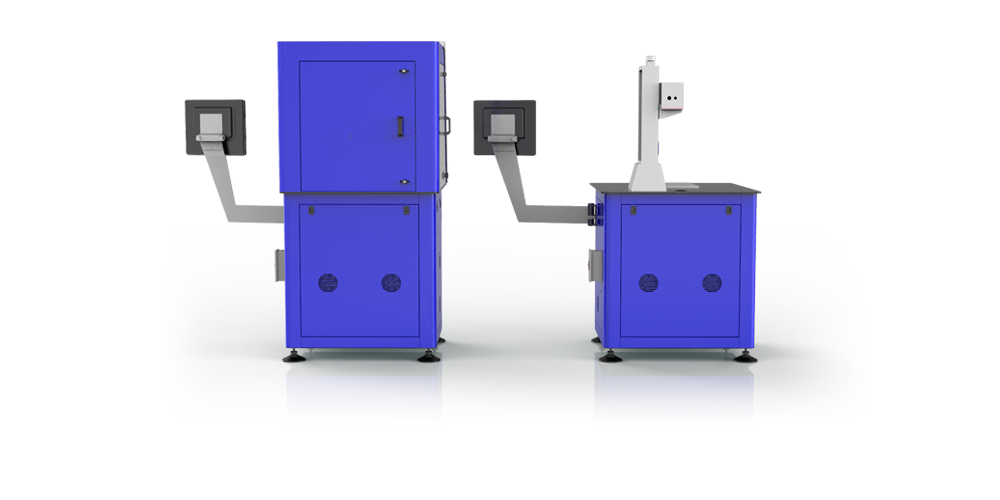

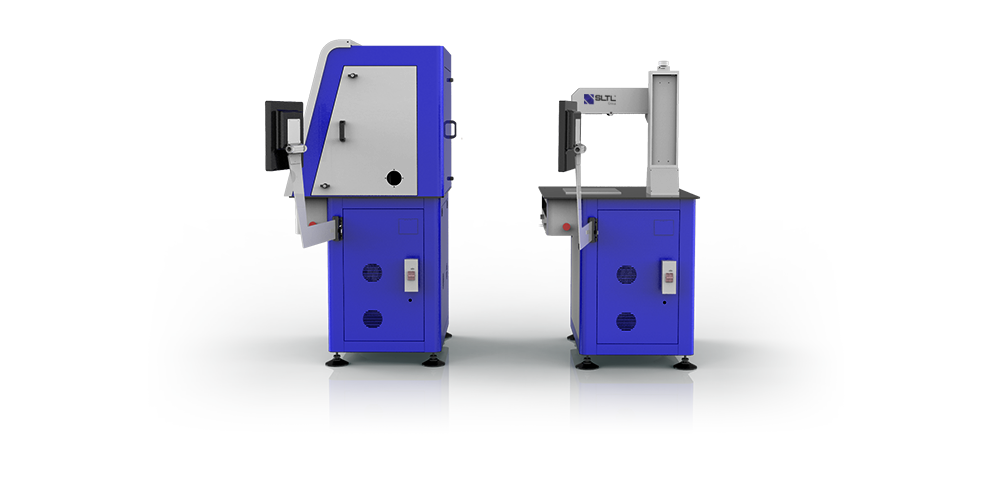

SLTL Ultra Fiber Laser Marking Machine

SLTL Group has been producing benchmark Laser Marking systems. With a range of laser marking machines that are differentiated based on the application; SLTL has been working ahead of time. The smart machines are capable of marking all the materials ranging from metals to non-metals. And the marking possibilities are endless, to name a few; applications like marking/ engraving, coloured marking, rotary marking, hallmarking, printing, coding, and traceability. It incredibly imprints over smaller to larger components. Regardless of whether you are a big or a small firm, established or a Start-up, producing small or large-volume components or handling small or large lot sizes – SLTL’s Ultra laser marking systems ensure the best possible ergonomics and safety at all times. Ultra can be efficiently used for marking medical devices which is challenging for medical device manufacturers.

| Unit | ||

|---|---|---|

| Laser | Fiber Laser | |

| Laser Power | W | 20 | 30 | 50 | 60 | 100 |120 |

| Mode of Operation | Pulsed | |

| Maximum Peak Power | kW | >7.5 |

| Operating Temperature | Up to 40 °C | |

| Lens | F – Theta | |

| Wave Length | nm | 1060 ±10 |

| Repeatability | micron | ≤80 |

| Working Area | mm | 500 x 500 |

| Overall Size (L*B*H) | mm | 1300 x 850 x 1600 |

| Gross Weight | kg | 180 |

| Travel (Manual / Motorized) | mm | 300 |

| Maximum Job Load | kg | 100 |

| Software | Mark-Pro |

Features and Benefits

- this is a list item

- this is a list item

- this is a list item