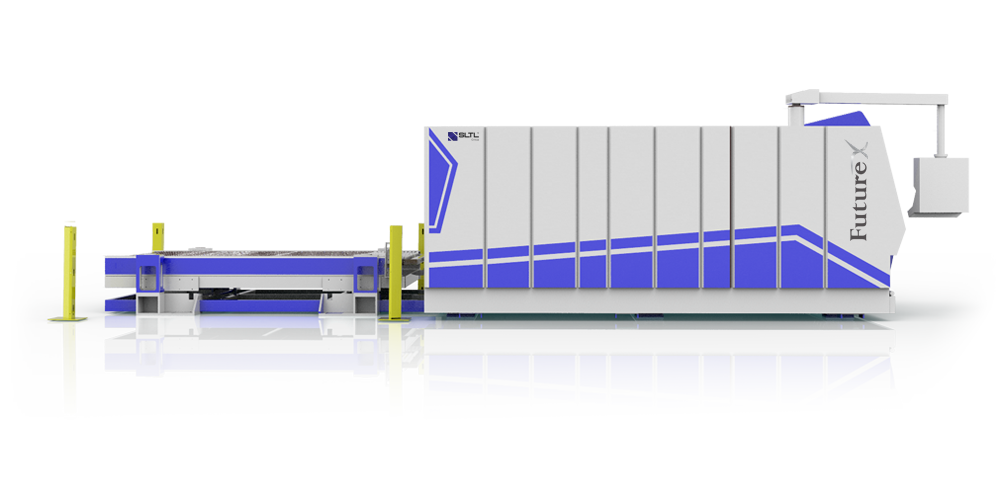

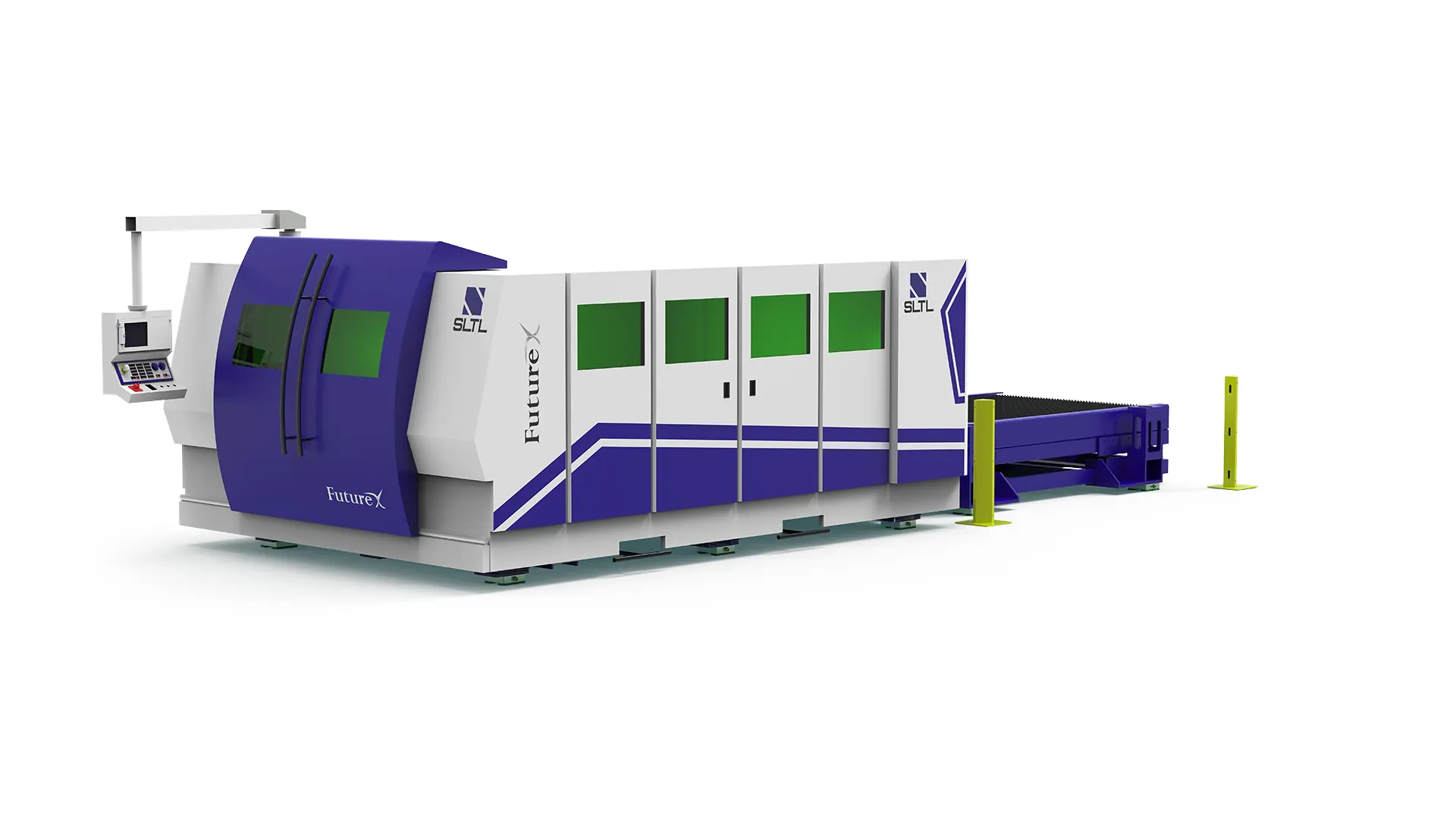

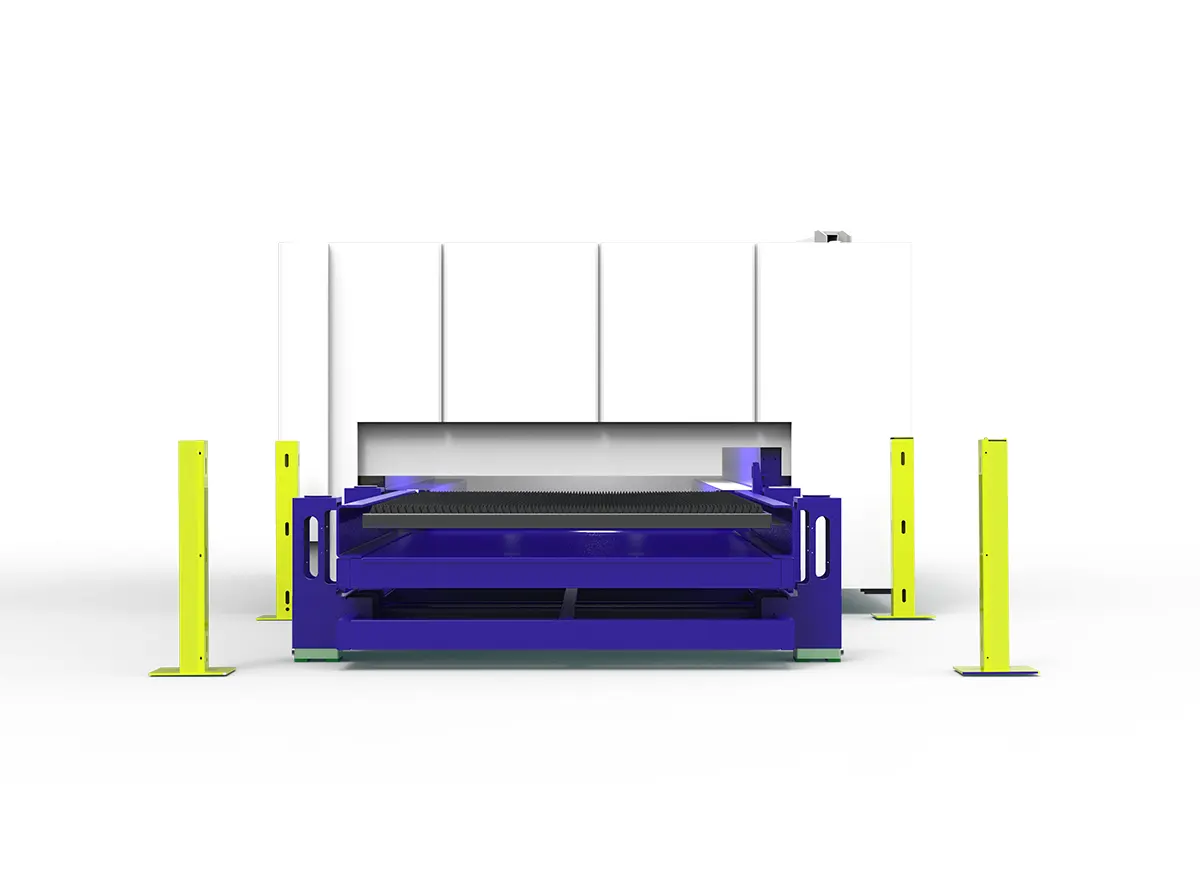

SLTL Future X 2D Fiber Laser

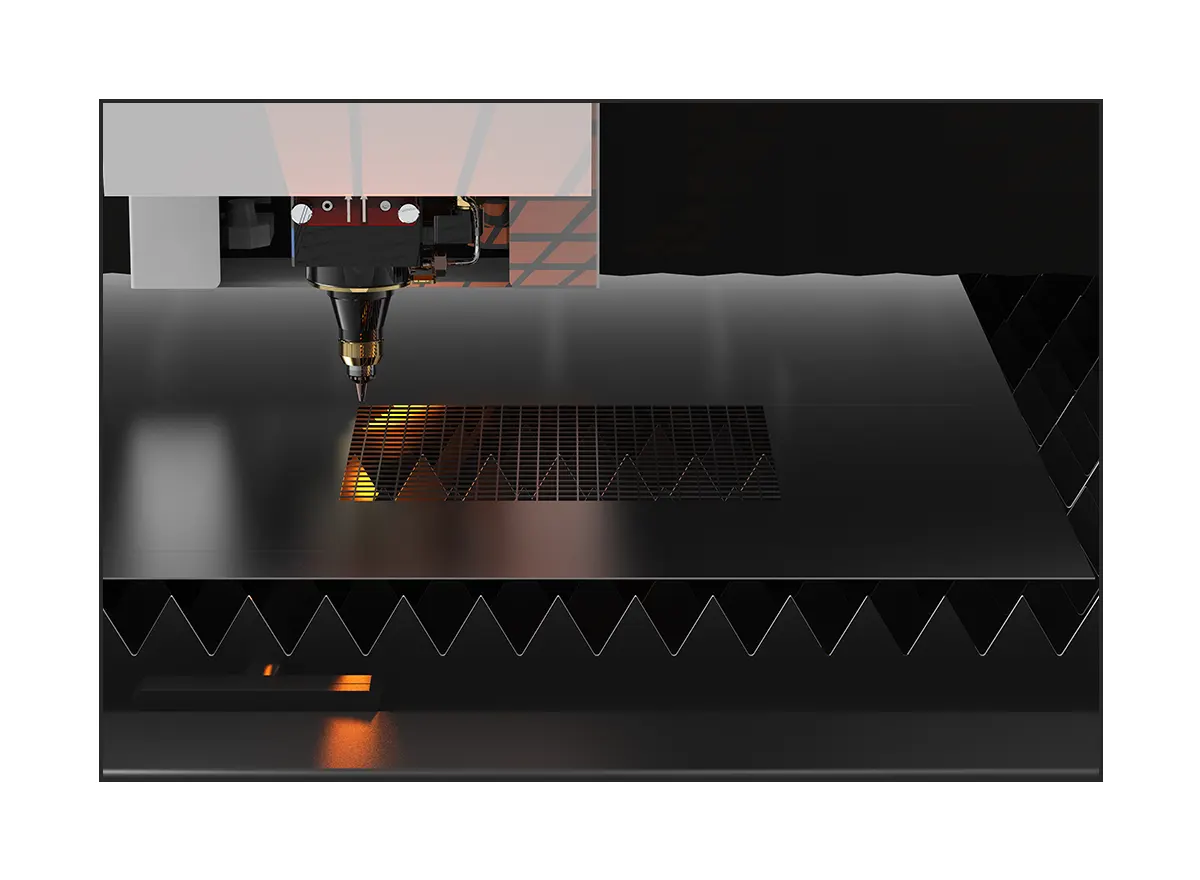

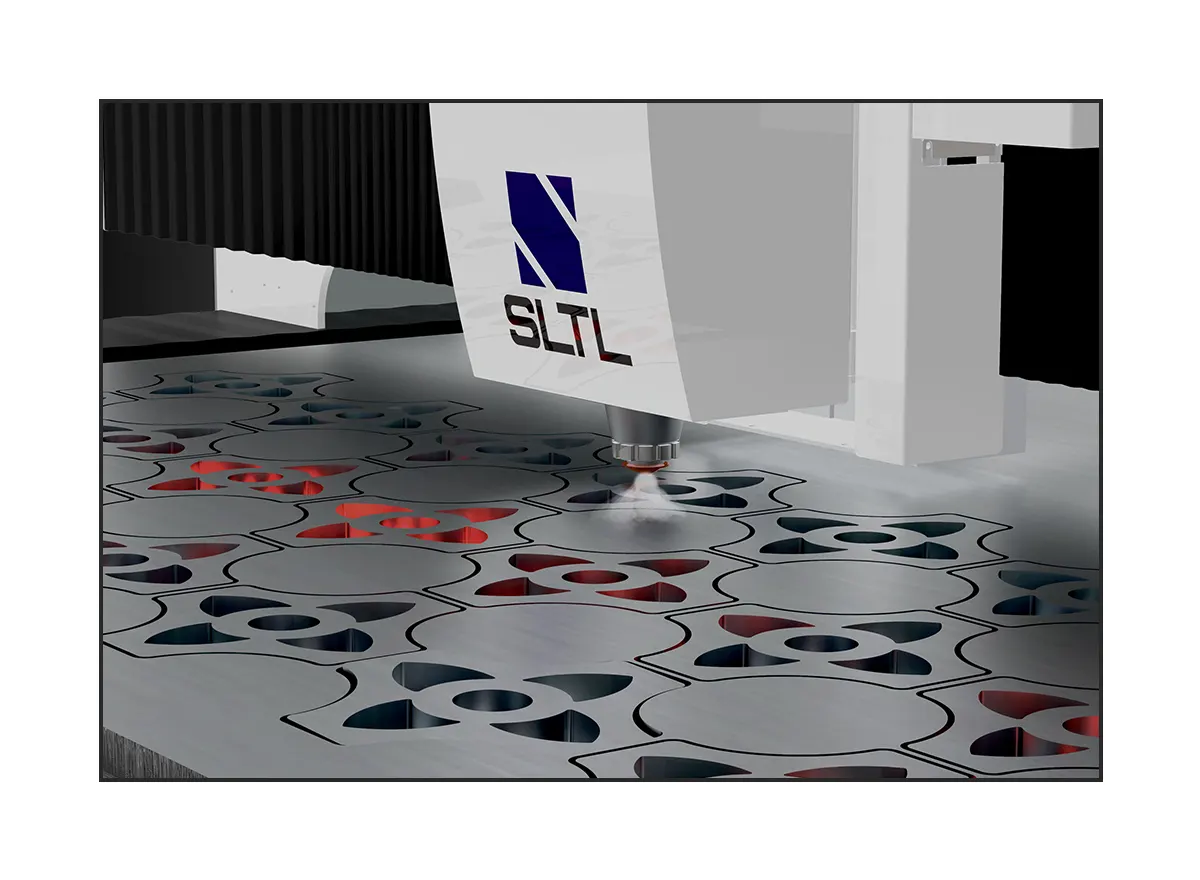

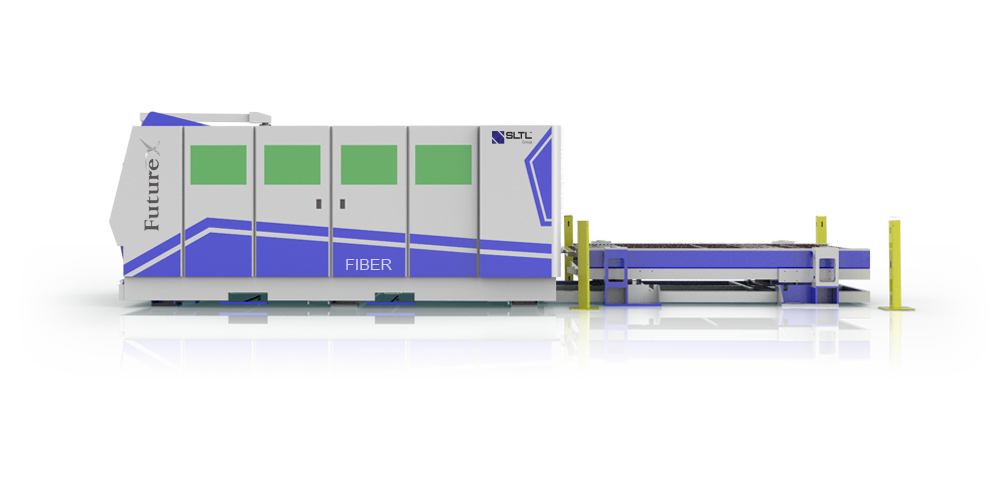

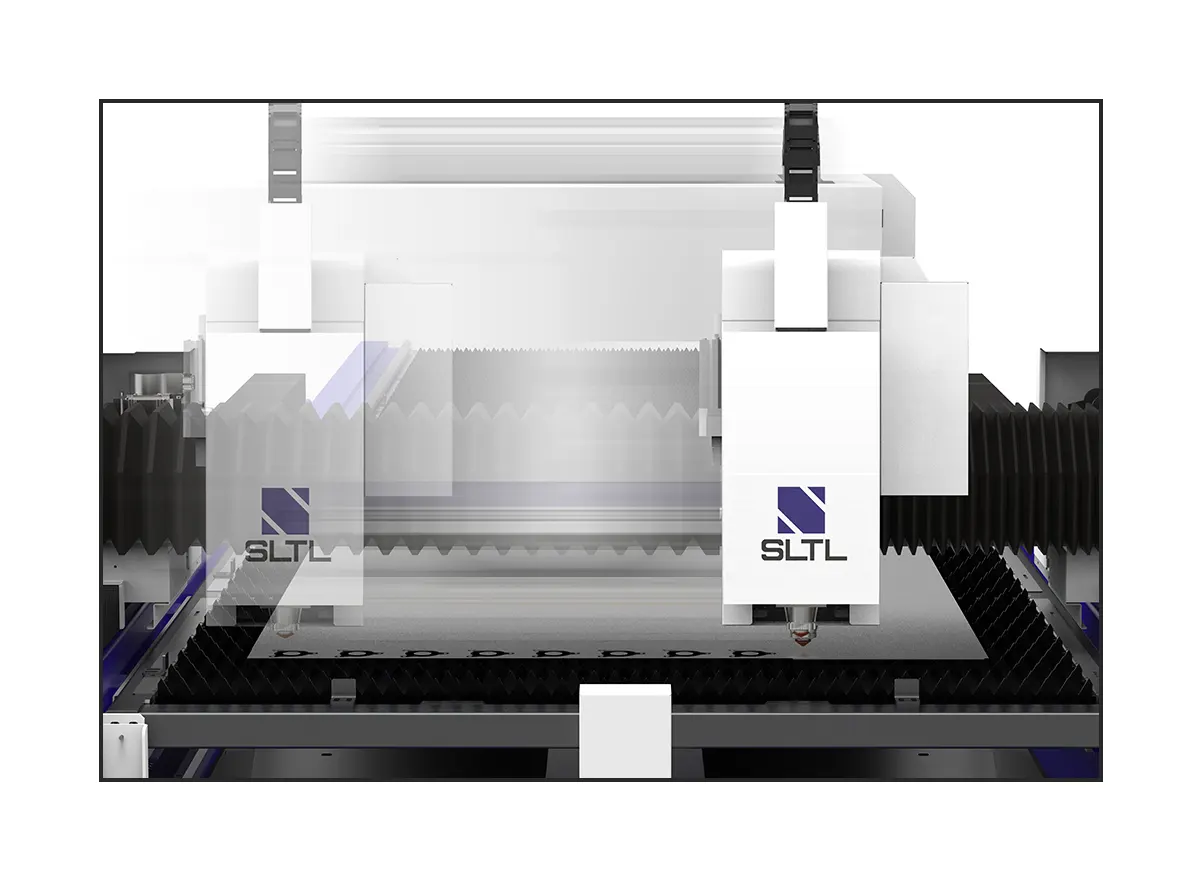

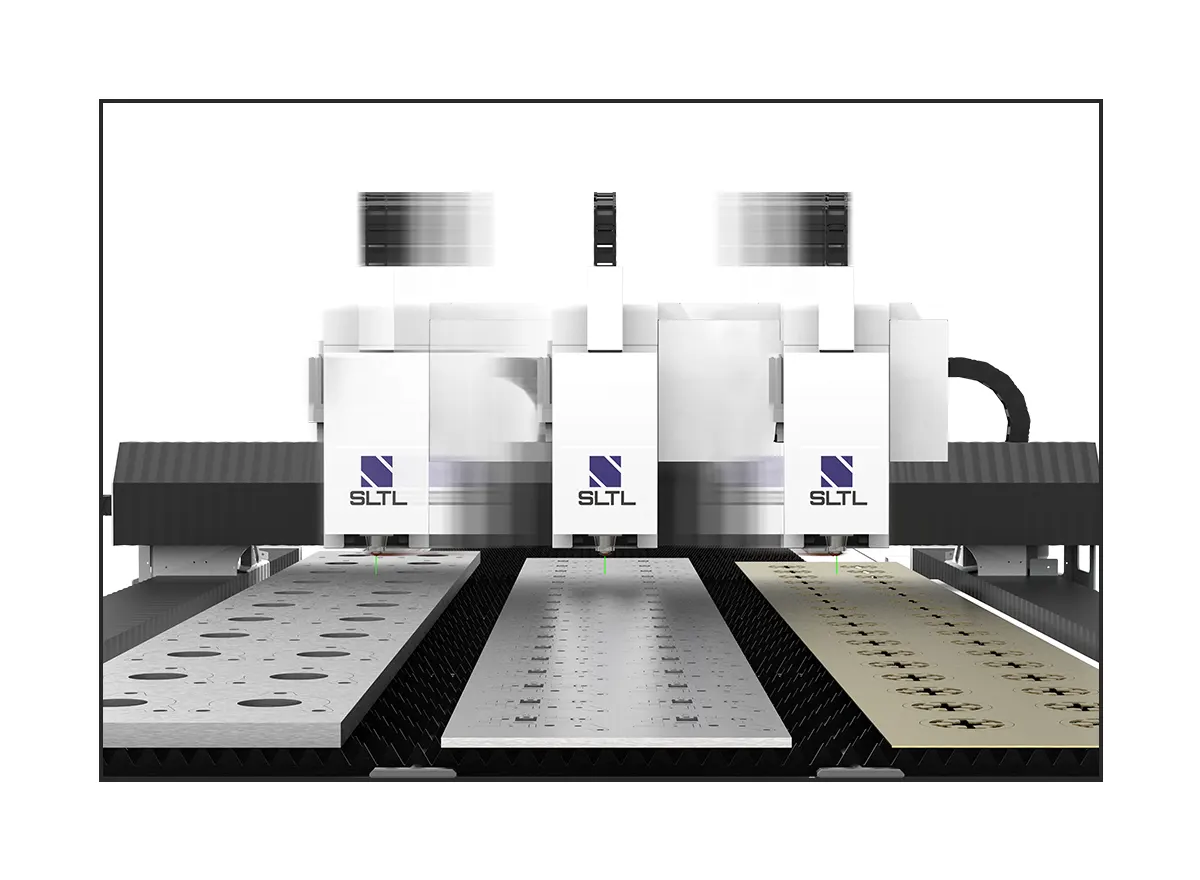

SLTL unveils & offers- The Future X a new generation High Power 2D Fiber Laser Cutting Machine for high precision sheet metal cutting, as the name suggests, it’s high on its factor X with its matchless instinctive reflexes. The Future X model is equipped with Dynamic Edge Control and a linear motor drive with a rigid gantry structure enabling 3G acceleration. The cost-effective 2D laser cutting system with up to 15 kW fiber laser and higher brilliantly cuts metals like mild steel, stainless steel, aluminium, brass, copper, titanium, and coated and textured metal sheets. Backed with dynamic edge control future X model is ultra-efficient, marvellously effective and its high performance makes it a must for your manufacturing unit.

| Laser Power (kW) | 6 | 8 | 10 | 12 | 15 | 20 | 30 |

|---|---|---|---|---|---|---|---|

| Mild Steel (MS) (O2) | 25 (1″)* | 28 (9/8″)* | 30 (19/16″)* | 40 (25/16″)* | 45 (7/4″)* | 50 (31/16″)* | 60 (19/8″)* |

| Mild Steel (MS) (N2 / Air) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* |

| Stainless Steel (SS) (O2) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″)* | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) |

| Stainless Steel (SS) (N2 / Air) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Aluminum (Al) (N2) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Brass (Br) (N2) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* |

| Copper (Cu) (O2) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 16 (5/8″) | 18 (11/16″) | 20 (13/16″) | 22 (7/8″) |

| Galvanized Iron (GI) (N2 / Air) # | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) |

| Power Consumption** | 32 kW | 40 kW | 48 kW | 56 kW | 68 kW | 85 kW | 120 kW |

| Working Area (X Y Z) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) | 1550 X 3030 X 150mm (60″ X 120″ X 6″) |

| Maximum Speed (X Y) | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* | 220 m/min (4724 ipm)* |

| Position Accuracy | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) | (±)0.0050 mm (0.0002″) |

| Repeatability | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) | (±)0.020 mm (0.001″) |

| Work Piece Weight | 900 kg | 900 kg | 900 kg | 900 kg | 900 kg | 900 kg | 900 kg |

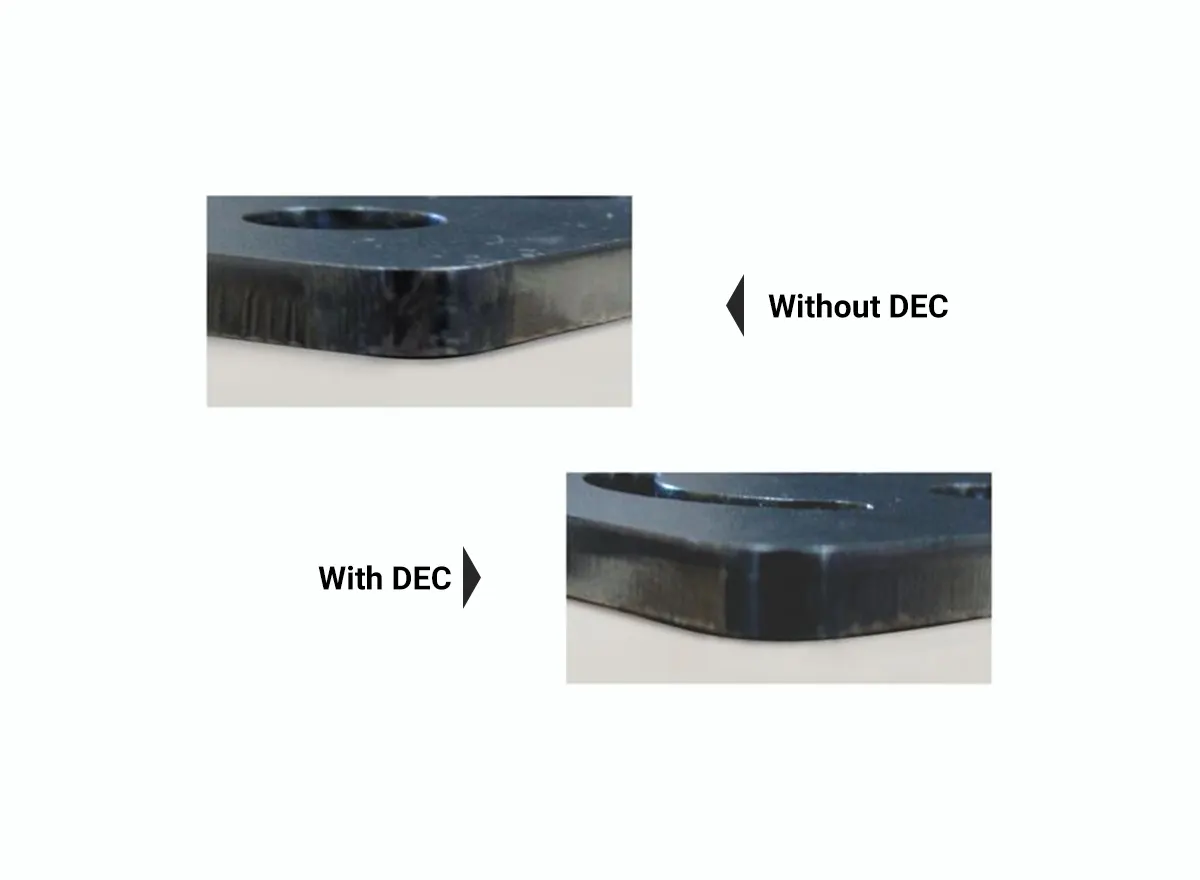

A laser, when properly focused and set for a material, cuts a part with a sharp edge. Dynamic Edge Control (DEC) decreases inflammation on the edges of the processing materials, synchronized laser with axial motion through the system. The cutting system operates laser power with the axis speed via the dynamic edge control (DEC) mechanism which reduces burning effects at the edges.