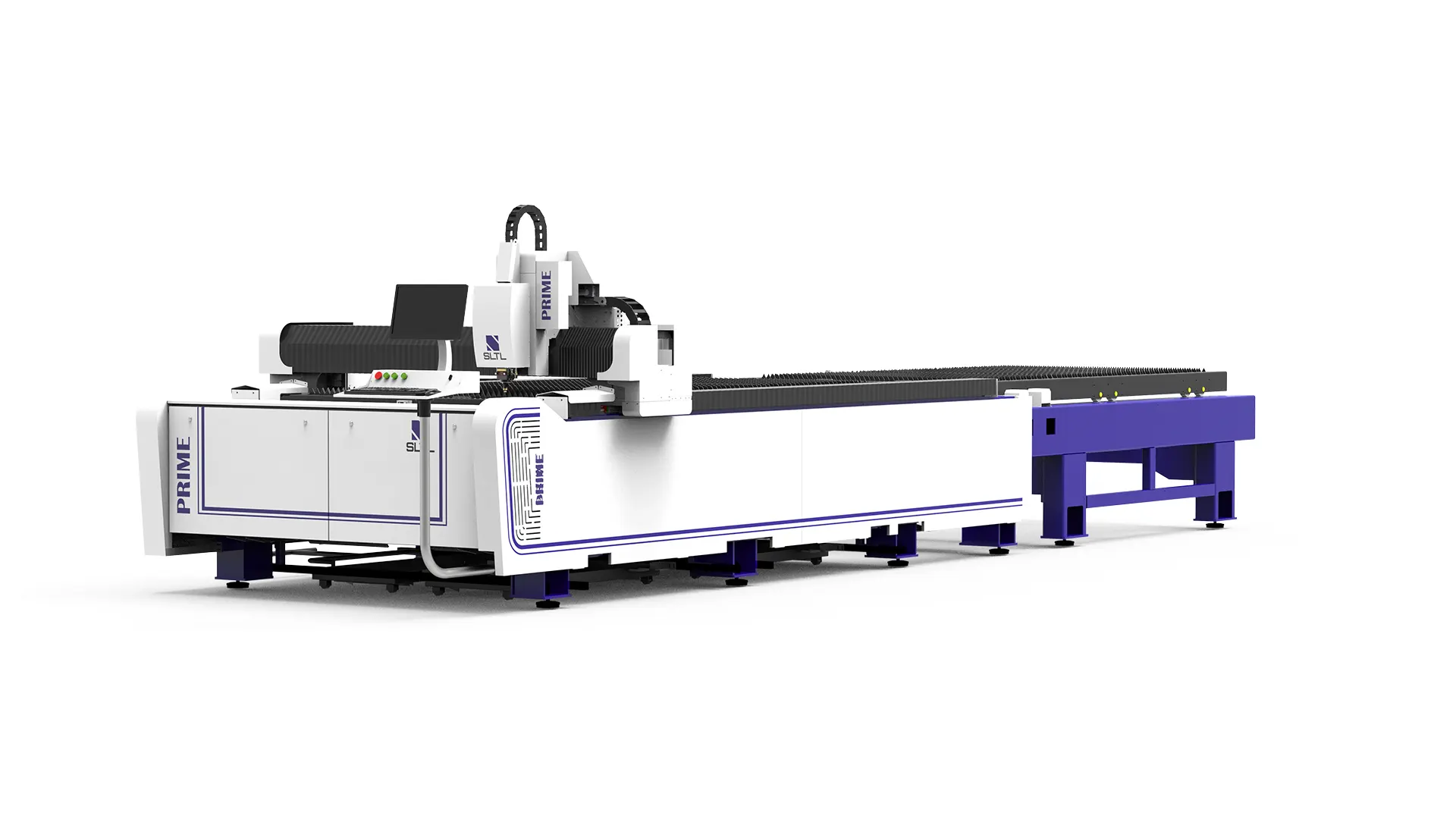

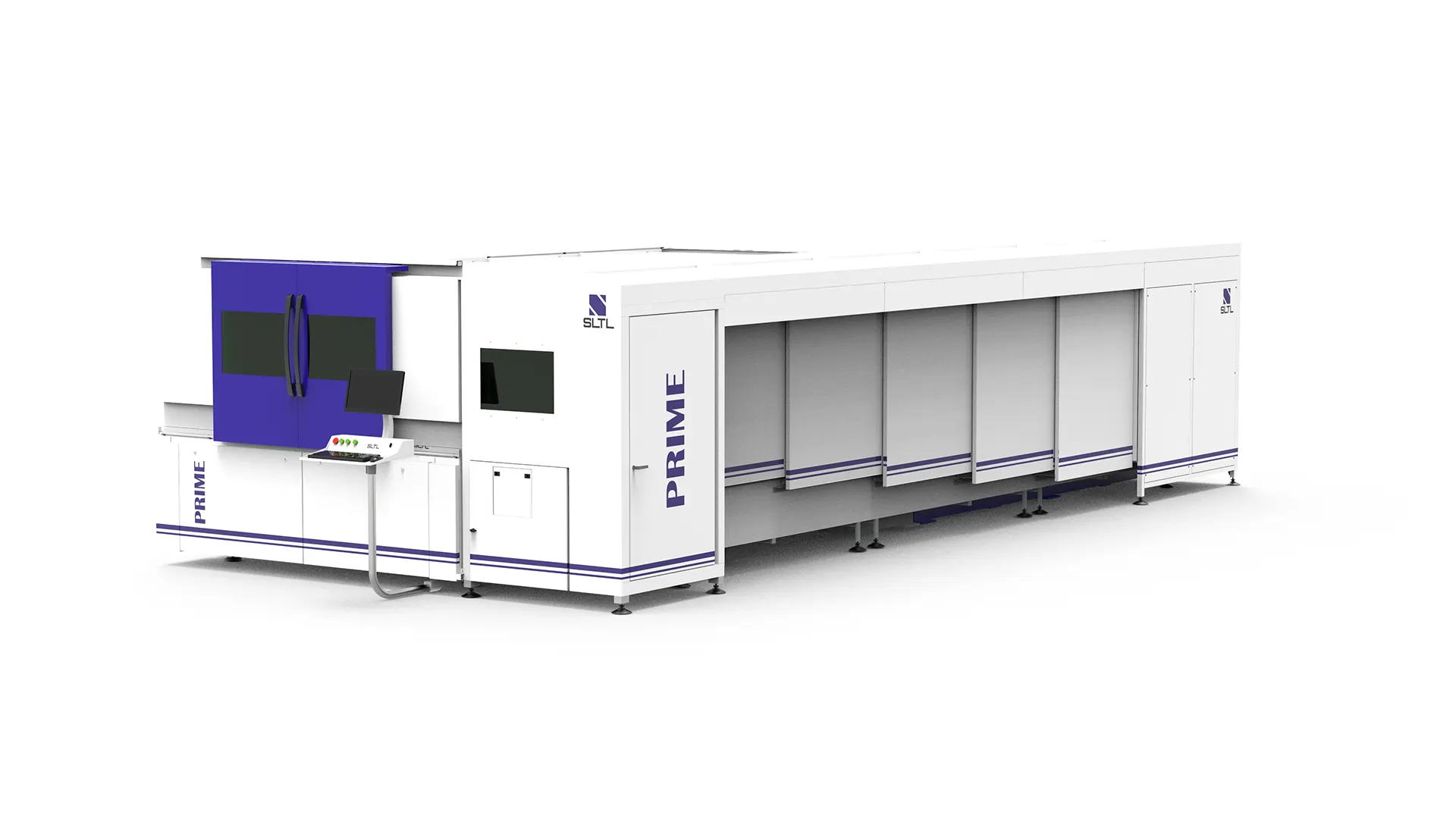

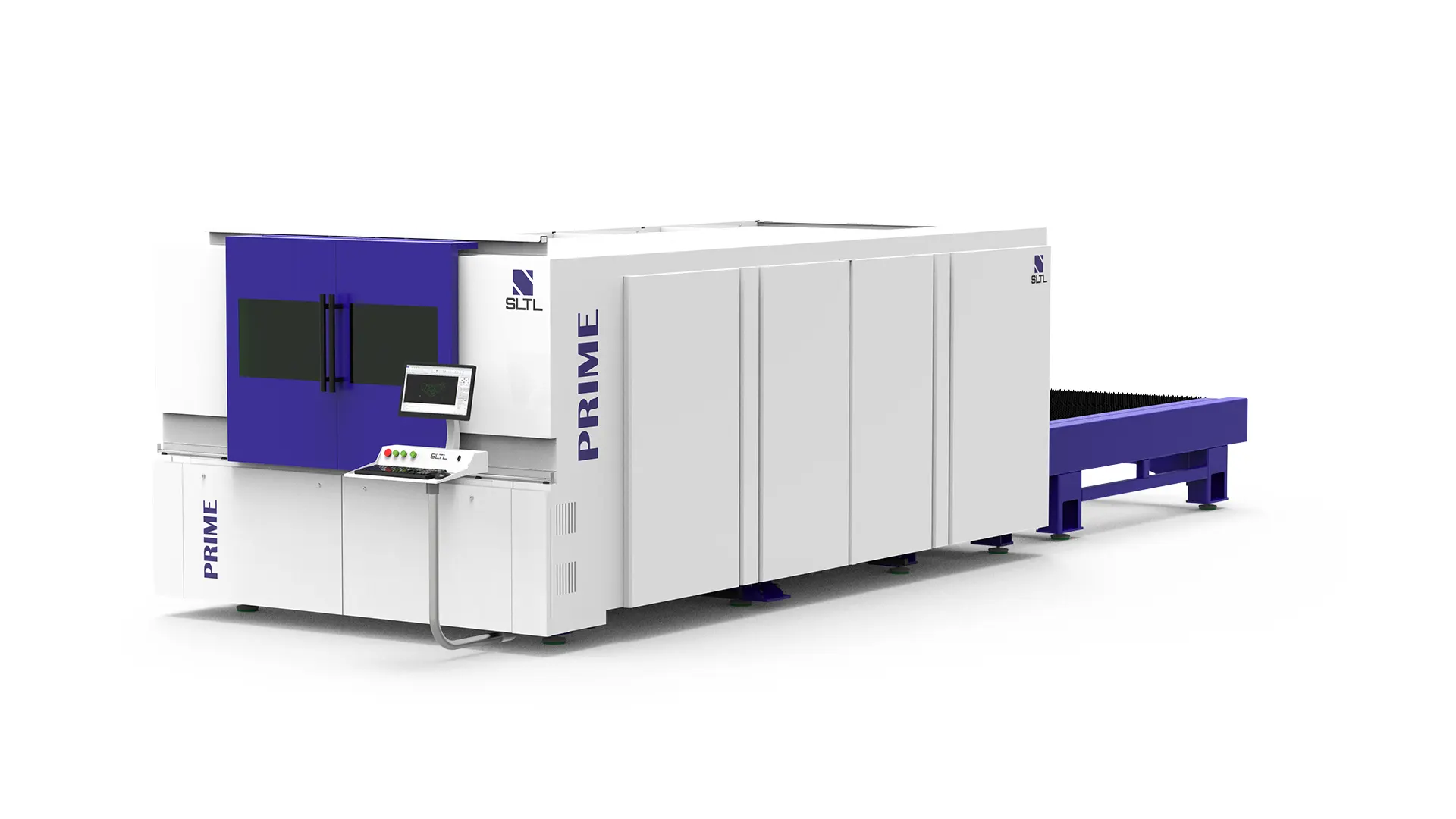

SLTL Prime 2D Fiber Laser

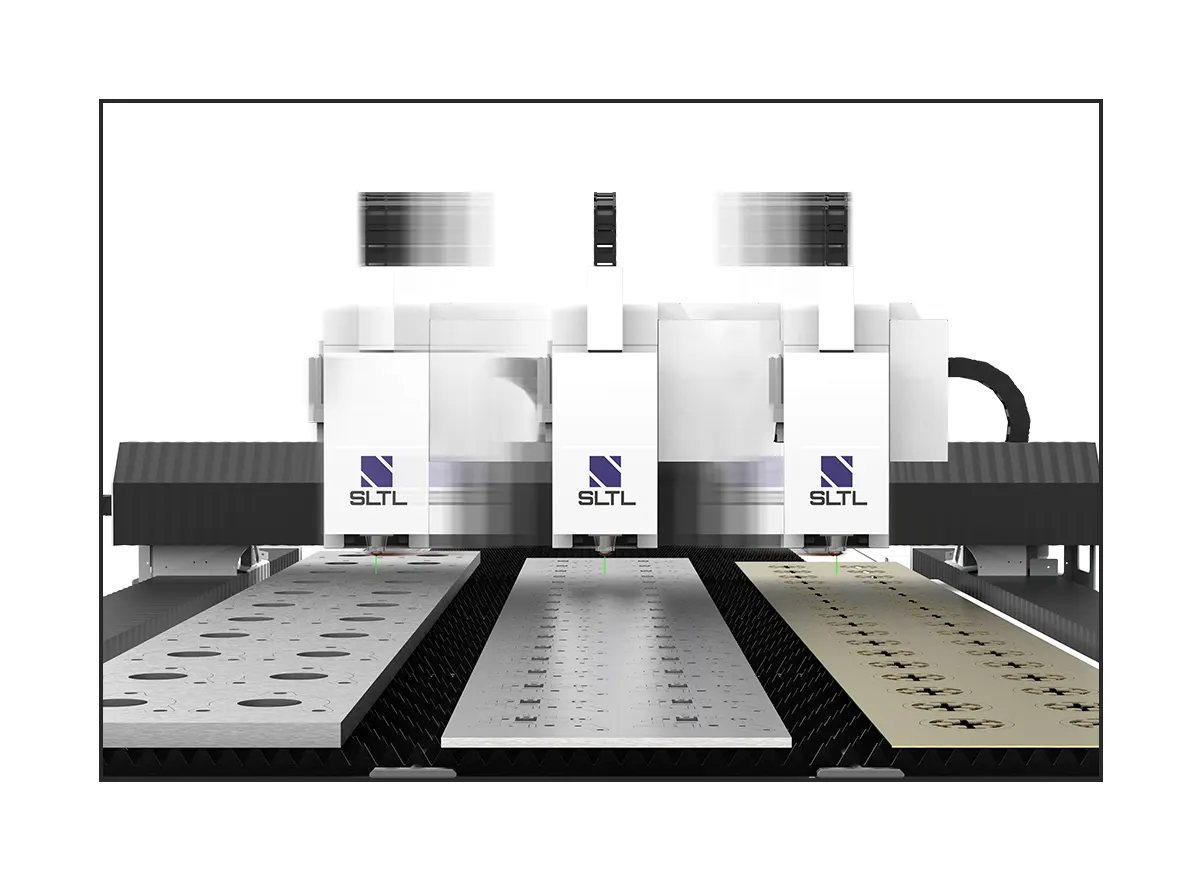

PRIME is a byproduct of the SLTL Group’s trademark Brahmastra Laser Cutting series. It is designed to help the modern-day manufacturer achieve optimum control of production, both qualitative and quantitative. The system is equipped with SLTL’s in-house developed software, making it the most robust machine in the market.

The intelligent hardware and software enable variable cutting at high rates without sacrificing cut quality or output. The system is designed for fabricators ready to start with the Laser Cutting Technology and expecting the highest results at an economical price. These machines are well-known for their flexibility and innovative features, making them a must-have for the sheet metal industry.

| Unit | 3015 | 4020 | 6520 | 6525 | ||

|---|---|---|---|---|---|---|

| Maximum Working Range | X Axis | mm | 1550 | 2100 | 2100 | 2550 |

| Maximum Working Range | Y Axis | mm | 3100 | 4100 | 6600 | 6600 |

| Maximum Working Range | Z Axis | mm | 300 | 300 | 300 | 300 |

| Maximum Workpiece Weight | kgs | 900 | 1650 | 2650 | 3100 | |

| Positioning Precision | mm/meter | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| Repeatability | mm/meter | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

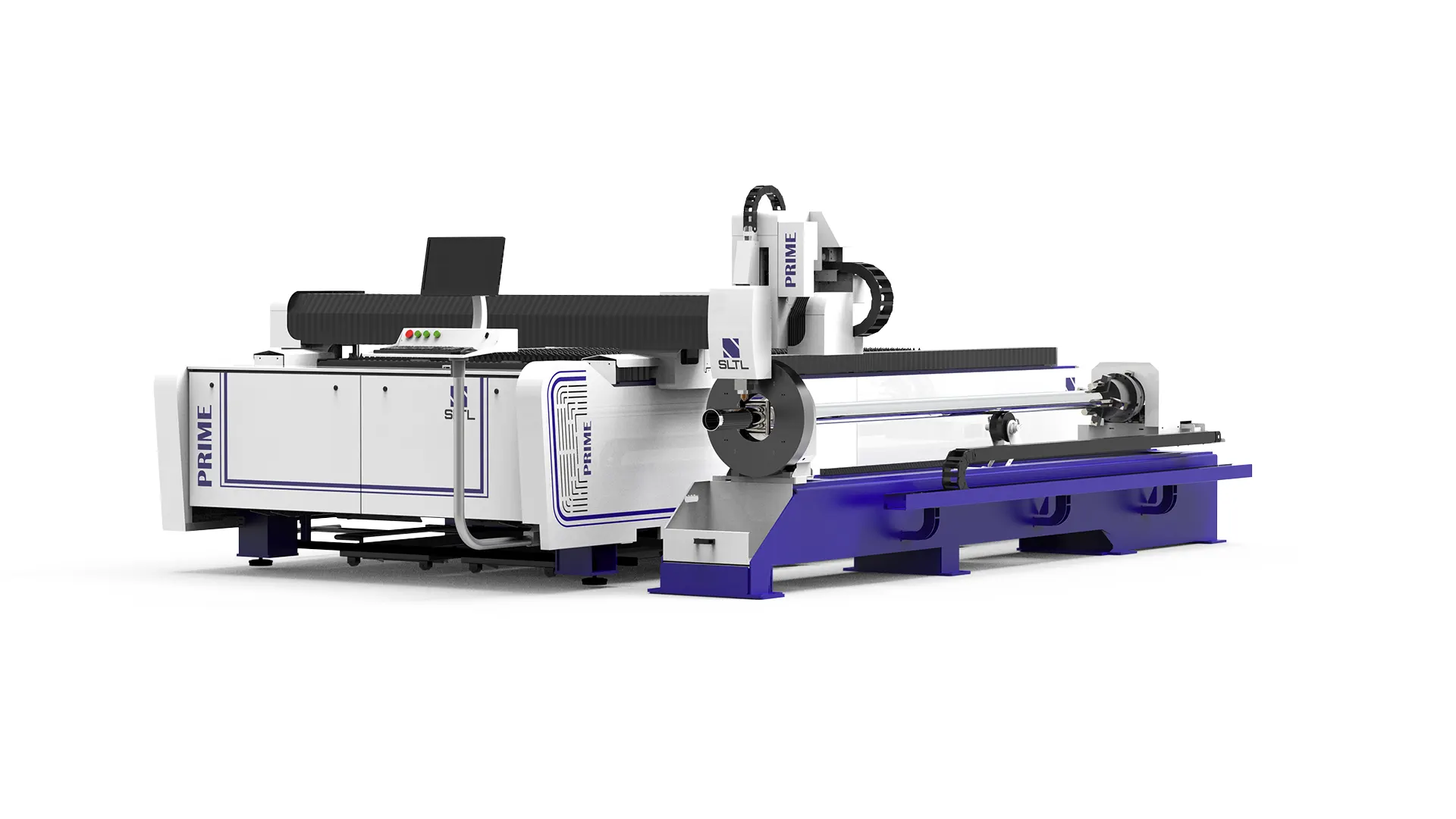

| Unit | ||||

|---|---|---|---|---|

| 3 m | 6 m | |||

| Maximum Working Range (Axis) | X x Y x Z | mm | 2200 x 3100 x 300 | 2200 x 3100 x 300 |

| Maximum Pipe size | Round | mm | 25 to 180 | 25 to 180 |

| Maximum Pipe size | Square | mm | 25 to 150 | 25 to 150 |

| Maximum Pipe size | Rectangular | mm | 25 to 150 | 25 to 150 |

| Maximum Job Weight | kgs | 70 | 140 | |

| Maximum Pipe Cutting Length | mm | 2500 | 5500 | |

| 4 Jaw Chuck Dia. (Feeding Chuck) | Size | mm | 200 | 200 |

| 4 Jaw Chuck Dia. (Feeding Chuck) | Operation | – | Manual / Auto | Manual / Auto |

| Laser Power | 1 kW | 1.5 kW | 3 kW | 4 kW | 6 kW |

|---|---|---|---|---|---|

| Mild Steel (MS) | 10 (3/8Ó) | 12 (1/2Ó) | 16 (5/8Ó) | 22 (3/4Ó) | 25 (1Ó) |

| Stainless Steel (SS) (O?) | 6 (1/4Ó) | 8 (5/16Ó) | 10 (3/18Ó) | 10 (3/8Ó) | 10 (3/8Ó) |

| Stainless Steel (SS) (N?) | 3 (1/8Ó) | 4 (5/32Ó) | 6 (1/4Ó) | 12 (1/2Ó) | 16 (5/8Ó) |

| Aluminum (AL) | 2** | 3 (1/8Ó) | 5 (3/16Ó) | 10 (3/8Ó) | 16 (5/8Ó) |

| Brass (Br) | 3** | 3 (1/8Ó) | 5 (3/16Ó) | 10 (3/8Ó) | 12 (1/2Ó) |

| Copper (Cu) | 2** | 2 (1/16Ó) | 3 (1/8Ó) | 6 (7/32Ó) | 8 (5/16Ó) |

| Galvanized Iron (GI)# | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* |

| Power Consumption*** | 10 kW | 12 kW | 17 kW | 24 kW | 32 kW |

.webp)

Common & Fly Cut

One of the key features to process high-speed cutting applications in Fiber laser cutting machines, FLYCUT performs the continuous cutting of the desired shape without lifting up the laser head giving a boost to the processing speed by reducing the head travel movements.

Highly Intelligent Nesting

Smart nesting software with a high level of intuitiveness that focuses on reducing processing time not only for the smaller designs but also for the larger parts. The software provides flexibility for users to add, change or delete programs on the go. It helps in achieving maximum precision and high speed with laser outputs of its peak power.

.webp)

.webp)

Auto Sheet Orientation

Speed up the cutting process by eliminating the manual alignment of the sheet for each cutting operation. Auto-sheet orientation feature enables automatic orienting of the program to that angle in which the sheet has been kept which ultimately eliminates the non-productive time of arranging the sheet.

User Friendly Software

Futuristic laser machine- Prime is integrated with Smart software that having a capability to draw and edit the basic all shapes in the software itself only. It is a user-friendly software that is easy to run the machine with all the foremost functionality available on the dashboard.

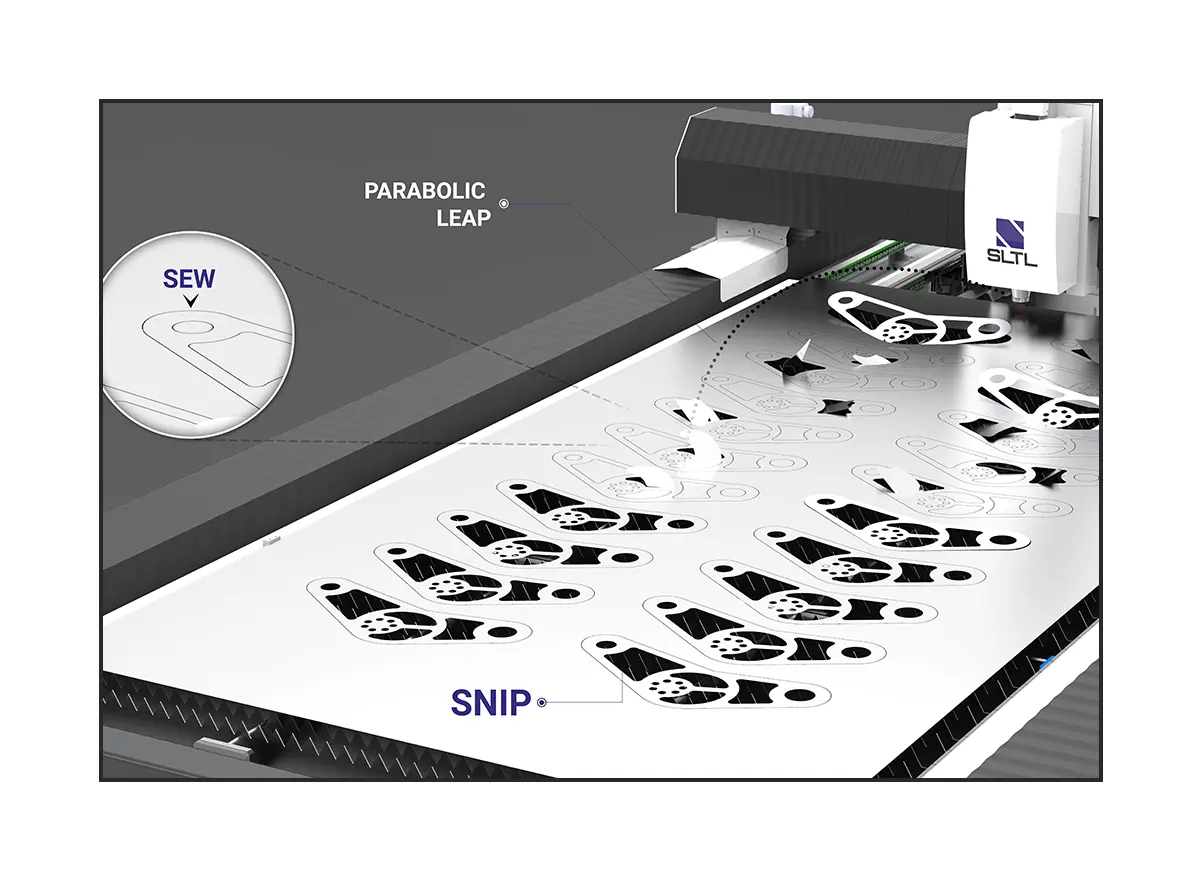

Anti-Collision Mechanism

The anti-collision mechanism consists of snip, sew and parabolic leaps, this minimizes non-productive times which can happen due to parts tipping over when cutting thin sheet metal, and ensures that the sheet cut-out pieces do not collide with the laser head while processing and makes your machine permanently productive.

Enhanced Productivity

Prime is equipped with ball support sheet loading/unloading mechanism which helps to load and unload the sheet effortlessly, ultimately eliminating the non-productivity time.

Dynamic Motorized Lens

With a dynamic motorized lens function, Prime can automatically adjust the focus to the most suitable position when processing different materials and thicknesses. It automatically changes the focus of the lens as per the object & the application. This will significantly improve the efficiency of the laser cutting machine and reduce the piercing time of thick sheets significantly with a high level of productivity.

Features and Benefits

- this is a list item

- this is a list item

- this is a list item